Home » Posts tagged 'wheat' (Page 4)

Tag Archives: wheat

Planting Wheat After Anhydrous

Every year in August and early September I get the question “How soon after applying NH3 can I sow wheat?”. Typically my answer has been a conservative one which takes into account rate, depth, spacing and soil moisture to end up with a range of 3 days to a week. The concern with anhydrous application is that when NH3 is placed in the soil it immediately turns into NH4 by striping H from H2O. This action releases OH into the soil in increases pH, depending on rate pH can reach 10.0 this hike in soil pH is a short term as the system disperrses and NH4 immediately begins the conversion to NO3 release H and driving down pH. The high pH in itself is not the problem but if the pH is still high and soil dries the OH will strip H from NH4 and NH3 is formed. The ammonia gas (NH3) is what can easily damage the sensitive seedling.

After fielding several calls in one day I wanted to dig a bit deeper and see what the science and specialist say. I was hoping for a nice consensus, haven’t found that yet. Here are some snip-its.

From Kansas State University

Dr. Dave Mengel

As a general rule, wait about 7 to 10 days between the anhydrous ammonia application and wheat planting. The higher the nitrogen rates and the wider the spacing (creating a higher concentration of ammonia in the band), the longer period of time you should wait. Also, in dry soils you may need to wait longer.

Canada Grains Council’s Complete Guide to Wheat Management Link

In the past, it was recommended that seeding be delayed for two days after banding anhydrous ammonia (NH3). However, in many soils as long as the NH3 is placed 5- 7.5 cm ( 2-3 inches) away from the seed, NH3 can be applied at the time of seeding. Seed damage from NH3 is most likely to occur under dry conditions on sandy soils when there is insufficient separation from the seed. Placement of fertilizer nitrogen should be deeper in sandy soils than in loams or heavy textured soils. Narrow band spacing 25 to 30 cm (10-12 in) is better than wider band spacing particularly under low moisture conditions.

From University on Minnesota

Peer reviewed publication

VARVEL: EFFECTS OF ANHYDROUS AMMONIA ON WHEAT AND BARLEY AGRONOMY JOURNAL, VOL. 74. NOVEMBER-DECEMBER 1982

Field experiments were conducted 1979-1981 on a Wheatville loam soil. The treatments consisted of three rates of N as anhydrous ammonia (45, 90, and 135 kg/ha) in 1979 and four rates of N (0, 45, 90, and 135 kg/ ha) in 1980-1981 at three depths (8,16, and 24 cm) in all combinations. Spring wheat and barley were then seeded at three different times. Seedling stand counts, grain yield, and protein were used to determine the effect of the treatments. Seedling stands were reduced in some cases, but no reduction in grain yield or protein was obtained due to the reduction in stand. The most important factor in spring anhydrous application was the depth of application, which caused greater moisture loss and seedbed disruption at the 24-cm application depth.

Spring wheat and barley response to N rates was similar at all depths of application (no significant interaction between N rate and application depth). The results indicate that anhydrous ammonia can be applied safely at planting time on spring wheat and barley, if applied at the 8 to 16 cm depth and at N rates currently used in the northern Great Plains.

From University on Minnesota (referring to corn) link

The only risk of planting soon after AA application is if seeds fall within the ammonia retention zone. To avoid seedling injury separation in time or space can be important. Under ideal soil moisture conditions and proper application depth of a typical agronomic rate normally there is little risk of seedling injury even if planted on top of the application zone right after AA application. That said, this can be risky and I would not recommend planting on top of the AA row. If you have RTK guidance it is very easy to apply AA between the future corn rows. If RTK guidance is not an option, I would recommend applying AA on an angle to the direction of planting to minimize the potential for planting on top of the AA band. If application conditions are less than ideal and you have no RTK guidance to ensure a safe distance from the AA band, then waiting 3 to 5 days before planting is typically enough time to reduce the risk of seedling injury.

From University on Wisconsin (referring to corn) Link

The depth of NH3 placement was the greatest factor in determined potential seedling damage. The time after application had little impact.

Iowa State University (referring to corn)

by Regis Voss, extension agronomist, Department of Agronomy

The wet fall and spring will cause anhydrous ammonia application and corn planting date to be close. This will lead to the oft asked question, “How long do I have to wait to plant corn after ammonia application?” If there is a soil separation between the ammonia zone and the seed, planting can be done the same day the ammonia is applied. If the seed is to be placed in the ammonia zone, the longer the waiting period the less potential for root injury. There is no magic number of days to wait.

My take home from several hours of reading research articles and factsheets was my favorite answer IT DEPENDS. I believe Regis Voss with ISU had it right, there is no magic number. The important aspects for determining time will be 1) Soil Moisture 2) N rate 3) Depth and 4) shank spacing. From the reading I think there may be some general rules of thumb.

On the conservative side with good soil moisture, NH3 placed at 6″ deep, rate below 80 lbs and spacing of about 15″ the next day should be ok. As any one of these factors change (drier soil, higher rates, shallower application, wider rows) the more time should be added to reduce risk. One thing to consider is field variability. While the field on average may have great moisture there could be dry spots, while on average you are 6″ deep with the NH3 there are areas the rig is bound to rise up and go shallow. So there is always a chance for hot spots. All of that said I could not find any research on this topic for winter wheat in the southern Great Plains much less Oklahoma. I will always tend to the safe side and suggest if possible to delay sowing a few days after applying anhydrous. However if time is critical proceed with caution.

Looks like I can add one more project to my list and I need to find some open ground and do some “Experimenting”.

Happy Sowing All!

Now may not be the time for Replacement

For phosphorus (P) and potassium (K) fertilizer management there are three primary schools of thought when it comes to rate recommendations. The three approaches are Build-up, Maintenance/Replacement, and Sufficiency. There is a time and place for each one of the methods however the current markets are making the decision for the 2016-16 winter wheat crop a very easy one. The OSU factsheet PSS-2266 goes in-depth on each of these methods. For the rest of the blog I will use P in the conversation but in many scenarios K should/could be treated the same.

Build-up is when soil test is below a significant amount of fertilizer, about 7.5 lbs P2O5 per 1 ppm increase, is added so that soil test values increase. This method is only suggested when grain price is high and fertilizer is relatively cheap. Given the market, this is a no go. The two most commonly used methods of recommendation are Replacement and Sufficiency. In the replacement approach if the soil is at or below optimum P2O5 rate it based upon replacing what the crop will remove. The sufficiency approach uses response curves to determine the rate of P that will maximize yield. These two values are typically quite different. A good way you boil the two down is that replacement feeds the soil and sufficiency feeds the plant.

Oklahoma State Universities Soil, Water, and Forage Analytical Lab (SWFAL) provides recommendations utilizing sufficiency only while many private labs and consultants use replacement or a blended approach. Some of this is due to region. Throughout the corn belt many lease agreement contain clauses that the soil test values should not decrease otherwise the renter pays for replacement after the lease is over. For the corn belt both corn and soybean can be expected to remove 80 to 100 pounds of P per year. Conversely the Oklahoma state average wheat crop removes 17 lbs P a year. In areas where wheat yields are below 40 bushel per acre (bpa) using the sufficiency approach for P recs can increase soil test P over time.

This conceptual soil test response curve is divided into categories that correspond with below opti-mum, optimum and above optimum soil test values. The critical level is the soil test level, below which a crop response to a nutrient application may be expected, and above which no crop response is expected. At very high soil test levels crop yield may decrease.

*Rutgers Cooperative Extension Service FS719

Back to subject of this blog, consultants, agronomist, and producers need to take a good look at the way P recs are being made this year. Profitability and staying in the black is the number 1, 2, and 3 topic being discussed right now. The simple fact is there is no economic benefit to apply rate above crop need, regardless of yield level. The figures above demonstrate both the yield response to fertilizer based upon soil test. At the point of Critical level crop response / increase in yield is zero. What should also be understood is that in the replacement approach P fertilizer is still added even when soil test is in Optimum level. This also referred to as maintenance, or maintaining the current level of fertility by replacing removal. If your program is a replacement program this is not a recommendation to drop it completely. Over a period of time of high removal soil test P levels can and will be drawn down. But one year or even two years of fertilizing 100 bpa wheat based on sufficiency will not drop soil test levels. On average soils contain between 400 and 6000 pounds of total phosphorus which in the soil in three over arching forms plant available, labile, and fixed. Plant available is well plant available and fixed is non plant available. The labile form is intermediate form of P. When P is labile it can be easily converted to plant available or fixed. When a plant takes up P the system will convert labile P into available P. When we apply P fertilizer the greatest majority of was is applied makes it to the labile and fixed forms in a relatively short period of time. For more in-depth information on P in the soil you can visit the SOIL 4234 Soil Fertility course and watch recorded lectures Fall 2015 10 26-30 Link .

How to tell if your P recs have a replacement factor, not including calling your agronomist. First replacement recs are based on yield goal, so if you change your yield goal your rate will change. The other and easier way is to compare your rates to the table below. Most of the regional Land Grant Universities have very similar sufficiency recs for wheat. Another aspect of the sufficiency approach is the percent sufficiency value itself. The sufficiency can provide one more layer in the decision making process for those who are near the critical or 100% level. Response and likelihood of response to P is not equal. At the lowest levels the likelihood of response is very high and the yield increase per unit of fertilizer is the greatest. As soil test values near critical (32.5 ppm or 65 STP) the likelihood of response and amount of yield increase due to fertilizer P decreases significantly. At a STP of 10 the crop will only produce 70% of its environmental potential if P is not added while at a STP of 40 the crop will make 90% of its potential. The combination of % sufficiency and yield goal can be used to determine economic value of added P.

*From Oklahoma State University Soil Test Interpretations. Fact Sheet PSS-2225

*Based on Mehlich 3

*PPM (parts per million) is used by most labs

*STP (soil test P) is a conversion used by some Universities. Equivalent to pounds per acre.

* for a 0-6” in soil sample PPM * 2 = STP.

This data is available from OSU in multiple forms from the Factsheet PSS-2225, the SWFAL website, Pete Sheets quick cards, and the Field Guide App.

This year with margins tight soil testing is more important than ever before. Knowing the likelihood of response and appropriate amount of fertilizer to apply will be critical maximizing the return on fertilizer invest while maximizing the quality and amount of grain we can produce. Visit with your consultant or agronomist to discuss what the best approach is for your operation. Lets ride this market out, get the most out of every input and come out of this down cycle strong.

Feel free to contact me with any questions you may have.

Brian

b.arnall@okstate.edu

2015-16 Wheat Crop Nitrogen Review

From trials to phone calls (and text messages, and tweets, and ect. ect) I have gathered a fairly good picture of this years winter wheat nitrogen story. And as normal, nothing was normal. Overall I seen/heard three distinct trends 1) Did not take much to make a lot 2) took a ton to make a lot 3) saw a response (N-rich strip or cow-pow) but fertilizer never kicked in. Covers most of the options, doesn’t it.

The N-rich strips really came out over all very good this year. N-Rich Strip Blog. On average many of those using the N-Rich Strip and SBNRC (SBNRC Blog) producers have been getting in the neighborhood of 1.0-1.3 lbs of N applied per bushel produced. This year the numbers ran from 0.66 to 2.3 lbs of N per bushel. In both extremes I believe it can be explained via the field history and the N-Cycle.

Nitrogen Cycle Pete’s Sheet

In at least two fields, documented with calibrated yield monitors, the N-Rich Strip and SBNRC lead to massive yields on limited N. One quarter of IBA bumped 86 bpa average on 47 lbs of N while a second quarter, also IBA, managed 94 bpa average on about 52 units of N. We are currently running grain samples from these fields to look protein levels.

The other side of the boat were those with N-Rich strip calling for +2.0 lbs N per bushel. I had received notes from producers without N-rich strips saying that they could predict yield based on the amount of N applied and it was a 2 to 1 ratio. Not always but many of these high N demand fields where wheat following a summer or double crop or corn or sorghum. While many of the low N demand fields were wheat after wheat or wheat after canola. In a rotational study that had been first implemented in the 2014-15 crop year I saw big differences due to previous crop. The picture below was taken in early March. The straw residue in wheat after wheat had just sucked up the nitrogen. While it was evident the residue from the canola broke down at a much more rapid pace releasing any and all residual nutrients early.

The yield differences were striking. The canola rotation benefited the un-fertilized plots by 22 bpa and even with 90 lbs of N applied having canola in the rotation increased yields by 12 bpa. We are looking and grain quality and residual soil sample now. I am sure there will be a more indepth blog to follow.

Another BIG story from the 2015-16 wheat crop was the lack of benefit from any N applied pre-plant. It really took top-dress N this year to make a crop. Due to our wet early fall and prolong cold winter N applied pre was either lost or tied up late. Work by Dr. Ruans Soil Fertility Program really documented the lack luster pre-plant N effect. The figure below shows 4 location of a rate by timing student. The number at the bottom of each graph is a rate by time (30/0 means 30 lbs Pre-0 lbs Top, 60/30 means 60 lbs Pre-30 lbs Top). At every single location 0/60 beat 60/0. Top-dress N was better than Pre-plant N.

Figure 1. Work from Ethan Driver and Dr. Bill Raun. Study looked at rate and timing of N fertilization in wheat. Treatments are ordered by total N applied.

The last observation was lack of response from applied N even though the crop was deficient. Seen this in both the NE and NW corners. I would hazard with most of the circumstance it was due to a tie up of applied N by the previous crops residue. The length at which the winter stretched into spring residue break down was also delayed.

Take Home

Here it is folks APPLY NITROGEN RICH STRIPS. Just do it, 18 years of research preformed in Oklahoma on winter wheat says it works. Hold off on heavy pre-plant N even if anhydrous is cheap. It does matter how cheap it is if it doesn’t make it to the crop. Will we see another year like 2015-16, do not know and not willing to place money on either side. What we do know is in Oklahoma split applying nitrogen allows you to take weather into account and the N-Rich strip pays dividends.

There are several fact sheets available on top-dressing N and the application of N-Rich strips. Contact your local Oklahoma Cooperative Extension Service county educator to get a copy and see if they have a GreenSeeker sensor on hand.

DAP vs MAP, Source may matter!

Historically the two primary sources of phosphorus have had different homes in Oklahoma. In general terms MAP (11-52-0) sales was focused in Panhandle and south west, while DAP (18-46-0) dominated the central plains. Now I see the availability of MAP is increasing in central Oklahoma. For many this is great, with MAP more P can be applied with less material. which can over all reduce the cost per acre. There is a significant amount of good research that documents that source of phosphorus seldom matters. However this said, there is a fairly large subset of the area that needs to watch what they buy and where they apply it.

If you are operating under optimum soil conditions the research shows time and time again source does not matter especially for a starter. In a recent study just completed by OSU multiple sources (dry, liquid, ortho, poly ect ect) of P were evaluated. Regardless of source there was no significant difference in yield. With the exception of the low pH site. The reason DAP was so predominate in central Ok, soil acidity. See an older blog on Banding P in acidic soils.

Figure 1. The cover of an extension brochure distributed in Oklahoma during the 1980s.

When DAP is applied, the soil solution pH surrounding the granule will be alkaline with a pH of 7.8-8.2. This is a two fold win on soil acidity aka aluminum (Al) toxicity. The increase in pH around the prill reduces Al content and extends the life of P, and as the pH comes back down the P ties up Al and allows the plant to keep going. However, the initial pH around the MAP granule ranges from an acid pH of 3.5-4.2. There is short term pH change in the opposite direction of DAP, however the the Al right around the prill becomes more available and in theory ties up P even faster.

Below is a table showing the yield, relative to untreated check, of in-furrow DAP and MAP treatments in winter wheat. The N401 location had a ph 6.1 while Perk (green) has a pH of 4.8. At Perkins in the low pH, both forms of P significantly increased yeild, almost 20 bushel on the average. DAP however was 5 bushel per acre better than MAP. At the N40 site the yield difference between the two sources was 1 bushel.

Relative yield winter wheat grain yield MAP and DAP both applied at equal rates of P (32 lbs P2O5 ac) when compared to a untreated check.

In general it can be said that in acid soils DAP will out preform MAP while in calcareous high pH soils MAP can out preform DAP. So regarding the earlier statement about the traditional sales area of MAP or DAP if you look at the soil pH of samples went into the Oklahoma State University Soil, Water, and Forage Analytical lab the distribution makes since.

Average soil pH of samples sent into OSU soil water forage analytical lab by county.

In the end game price point and accessibility drives the system. In soils with adequate soil pH levels, from about 5.7 to around 7.0, get the source which is cheapest per lbs of nutrient delivered and easiest to work with. But if you are banding phosphorus in row with your wheat crop because you have soil acidity, DAP should be your primary source.

Herbicide and UAN tank mixed for top-dress

Spring is the time that many wheat producers apply herbicide and nitrogen (N) fertilizer. For many this can be accomplished in a single pass by tank mixing the herbicide and UAN. In most cases this is an effective practice which eliminates one pass over the field. There are some scenarios in which this practice is ill advised. One such scenario is high temperatures which would lead to excessive leaf burn and crop damage. The other scenario is no-till and that will be the focus of this article. Ruling out warm temperature tank mixing herbicides and nitrogen, assuming the herbicide can be tank mixed, is a good practice. No-till on the other hand can be a different issue.

Situations with a lot of residue and smaller wheat is common during top-dress.

The problem in no-till comes from the liquid application method needed to apply herbicides, flat flan. To get a good kill with the herbicide the spray pattern needs to have good coverage, i.e a lot of small droplets to ensure maximum surface area impacted. Unfortunately there are four primary fates of UAN when applied via flat fan nozzles. The UAN could be taken directly up into the wheat plant via absorption through the leaves, the UAN could reach the soil and go into the soil solution or absorbed onto the soil itself, the UAN can be taken up by weeds, or the UAN droplet may hit dead plant tissue and be adsorbed into the residue.

UAN applied with a flat fan will hit a growing plant, the soil, or residue.

The fourth fate of UAN presented is what can make the tank mix less efficient than a two pass system. In a no-till system any UAN that hits residue should be counted as lost, for the short term. The decision to go with a one pass or two pass system can be aided by evaluating the amount of canopy coverage. For example if the no-till field has 50% canopy coverage then one could estimate 50% of the UAN applied via a one pass system would be tied up in the residue. The cost of a second application could then be compared to the lost N. If 15 gallon of 28-0-0 was being applied then approximately 22.5 lbs of N would be tied up by the straw. At a price of $0.40 per lb on N, that is $9.00 worth of N. Conversely if the canopy coverage was 80% only 20% or 9 lbs of N would be tied up in the residue. Saving the $3.60 in nitrogen would not justify a second trip over the field. Luckily OSU recently released the Canopeo app which uses a cell phones camera to take pictures and quickly and accurately determine % canopy coverage. Canopeo is available for iOS and android http://canopeoapp.com/.

In fields with a high amount of residue or limited canopy coverage UAN should be applied with streamer nozzles. This will concentration the fertilizer into streams which will allow the UAN to have enough volume to move off the residue and into the soil.

So as the decision is being made to tank mix herbicide and UAN or make two passes take into consideration: % canopy coverage, rate of UAN (how much could be lost), cost of UAN per pound, and cost of a second trip over the field.

Below is an excerpt from the publication Best Management Practices for Nitrogen Fertilizer in Missouri; Peter C. Scharf and John A. Lory. http://plantsci.missouri.edu/nutrientmanagement/nitrogen/practices.htm

Broadcasting UAN solution (28 percent to 32 percent N) is not recommended when residue levels are high because of the potential for the N in the droplets to become tied up on the residue. Dribbling the solution in a surface band will reduce tie-up on residue, and knife or coulter injection will eliminate it. Limited research suggests that the same conclusions probably apply for grass hay or pasture. Broadcast UAN solution is also susceptible to volatile loss of N to the air in the same way as urea, but only half as much will be lost (half of the N in UAN solution is in the urea form).

Some thoughts on pre-plant nitrogen and a little outside the box thinking

It is that time of year, every Co-op I drove by the other day had a line of trucks pulling anhydrous tanks and the spinner spreaders were being loaded. For those of you who haven’t applied your nitrogen yet lets discuss the options traditional and nontraditional.

Anhydrous Ammonia, 82-0-0: by far the most widely used N source is the southern Great Plains. While it is not the most enjoyable to work with it is the cheapest per pound of N and that leads to its wide spread use without Oklahoma wheat production. Just a few simple rules with NH3, get it in the ground and close the row behind you. In conventional till this is usually easier unless the ground is too wet or too dry. In no-till this may be a little more challenging but usually easily accomplished. With the rise in low disturbance applicators I am seeing more and more acres of no-till receiving NH3. Last year I was in a field of stripper stubble and I had a hard time finding where the rig had run, minus wheel tracks.

Urea, 46-0-0: is second on the hit list in nitrogen sales in our state. It is a safe source that is easily handled and applied. In a conventional till system where the urea can be worked in shortly after application it is a very efficient and effective source. Unfortunately when it is applied to the soil surface and rain is the method of incorporation we can experience between 5-60% N losses. The losses come from how urea is converted to plant available ammonium (NH4). For urea (NH2)2CO2, to be converted to plant available NH4 it needs the enzyme urease. Urease is present everywhere but in the highest concentrations on plant residue. The figure below shows the reaction, urease converts urea into NH3 as soon as the prill dissolves. In the presence of moisture the NH3 (gas) is turned immediately to NH4 (solid) and is absorbed onto the soil particle.

The problems come when there is no soil particle for the NH4 to bind with. It usually takes 0.50 inches of rain or irrigation to fully dissolve and incorporate urea into the soil. So if we only get a few tenths or hundredths, even heavy dews, some of the urea will dissolve, be converted to NH3 then NH4 and be left on the plant/residue. When the moisture dries, some or all of the NH4 goes back to NH3 and will gas off into the atmosphere. I have even seen this happen when urea is applied on a wet/damp soil, not incorporated and it doesn’t rain for significant period of time. If the temps are cooler the urease is slower so less of the urea is converted to NH4, but if the temps are warm 60+ degrees these little enzymes can act very quickly.

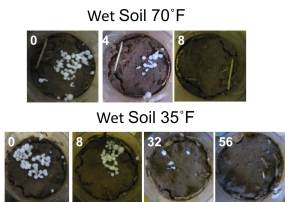

Urea placed on the surface of a wet soil under two temperature regimes. White text is the number of hours after application.

Urea placed on dry soil, Top row: dry soil no water added, Bottom left, moisture added from subsurface, Bottom right : simulated rain fall event of 1/2″. White text is the number of hours after application.

Below is a short video on using urea fertilizer.

While the recent rains are a blessing and will surely help germination, it is not aiding our N use efficiency especially in no-till. That is why in some parts of the state you may see some grain drills running right now. Some of those producers are not planting wheat they are actually applying there pre-plant urea. I have even been told in the SW part of the start some producers are using air-seeders to apply their urea. While this seems like a costly venture I have worked with the Ag Economist to create a calculator to figure up the break even for when it would pay to use an air-seeder over the traditional spinner spreader in no-till. We hope to put the finishing touches on it in the next few days. When it is completed it will be shared on this blog.

Liquid Urea Ammonium Nitrate, 32-0-0 or 28-0-0: while this is one of the more expensive forms of N many producers are utilizing this source because the can pre buy and store on site and as sprayer get larger they can cover a significant amount of ground quickly. For the most part UAN is used in no-till and is a great source. I always recommend that applicators use streamer nozzle or streamer bars to apply UAN. When UAN is applied via a flat fan nozzle it spreads the fertilizer across the residue allowing a significant portion to be tied up. The streamers concentrate the fertilizer into streams/bands reducing contact with residue and increasing the amount of UAN that reaches the soil surface.

Timing and Rates

The cost of anhydrous, about $0.1 to 0.12 less per pound N less than urea is driving its use this year. The lower price is also driving a significant about of producers to go with 100% of their N pre-plant. While this makes for sound economics now having all of your N upfront is like putting all of your eggs in one basket. If we do get that cold and wet winter as some are calling for this presents a great chance for the N to move down the soil profile and down the slope. I have always recommended split application. This allows a producer to judge the crop throughout fall, winter and even yearly spring and adjust his or her N plan accordingly. For those who plan to graze there is still a need to get enough N down to produce fall forage, this may be 50 to 80 lbs of N, but for grain only production planted later in the fall a typical crop may only need 20-30 lbs of N before going into winter. The old rules of thumb, 2 lbs N per bushel and 30 lbs N per 100 lbs of gain still work and are better than a guestimate but we have better ways. Right now is the time to plan to apply N-rich strip, a strip in the field with 40 to 50 lbs more than the rest of the field. These strips can be applied with a variety of applicators, but as long as the N goes down in at least an area 10 ft wide by 300 ft long it is good to go.

Just a few of the applicators used for putting out N-Rich Strips. ATV Sprayer, Receiver Hitch mounted Sprayer, Road sprayer with a rear boom, pull type spinner, large sprayer, push spreader. Not shown is NH3 applicator.

Below is a N-Rich Strip 101 video.

If you have got the N-Rich strips out you can set back and watch to see when and if they develop. If you can see the strip you know you need too fertilize.

While many are not ready to think about top-dressing yet, it is never too early. Don’t be afraid to think outside the box. Oklahoma’s springs tend to present the perfect conditions for N loss when urea is the primary N source. This year in a 4R Top-dress Nitrogen Application Demo, at Lahoma and Chickasha, we are going to apply just about every available commercial source in about every possible manor. Urea will be broadcast, coated with inhibitors, applied with a grain drill, NH3 will be knifed in, and UAN will be applied with flat fan nozzles, streamer nozzles and knifed in. As technologies improve and the cost of N remains relatively high the options for top-dress N application will continue to improve. The economics of wheat production don’t look great right now so don’t be afraid to think outside the box, even if it does raise the eyebrows of your neighbors. Fill free to contact myself or your local extension educator if you have any questions about N application.

Agriculture Apps, 200 strong and growing

It was just 11 months ago when I wrote my last blog on Ag apps. Since that time I have presented on the topic several times, added nearly 100 new apps, have filmed several designated segment on sunup featuring apps (these can be seen at http://www.youtube.com/osunpk), and released two (soon to be three) apps myself. Below is the introductory slide I have been using in all of my app talks, on this slide you can see how the number of apps have been increasing overtime. In this update I wanted to share some of the new sections I have added to manage the vast number apps and go through some of my favorite apps in each of the sections.

Finding the right app has not changed as I still just give an app 3 minutes before a keep or drop decision is made, however since a year ago some of the key words are now less useful. For example a search for wheat will bring up droves of gluten free diet apps. None of these fit the bill for what I am looking for. Though out the blog you can click on pictures screenshots to get a better view of the app buttons.

Ag News and Weather

Still a very large section with little change for my recommendations, just go with what suits you in layout and reporting. I personally use RonOnRON (Ron Hays, the voice of Oklahoma Agriculture), DTN/PF, AG/Web, and AgWired.

Ag Resources

This includes peer review publications, resource guides and extension materials.

Calculators

The majority of the Calculator apps preform relatively simple functions without the need of cellular or wifi connectivity. The Ag PhDs have two apps in the section I want to highlight, HarvestLoss and Fert. Removal. Both apps are useful tools in making management decisions. HarvestLoss allows the user to calculate the economic loss of a poorly set combine while Fert. Removal allows the user to select from a wide range of crops and see an exit ate of nutrient removal based upon selected yield level. Other useful apps are Growing Degree which allows the user to see cumulative heat units a crop has received anywhere in the US, Corn Yield Calc estimates corn yield based on ear girth and length, Canola Calc is a great apps produced by Pioneer which calculates the proper planting rate of canola based upon several factors and the Kansas Wheat Yield Calculator KWYC, uses growth stage stalk counts, height and/or NDVI to estimate potential grain yield.

Crop Tools

This section is filled with University Extension handbooks such as Purdue’s Field Guide ($12.99), University of Arkansas Corn Advisor, University of Kentucky Corn Production, and one private groups MFA Agronomy. Each of these guides are quality apps and should be chosen based upon geography or personal preference. The university apps mirror their respective hard copies however UK’s app added a nice update section highlighting local Ag news. MFA’s app is strong in pesticides with good herbicide performance data.

Fertilizer

For any producer who regularly applies animal waste the Manure Calc by the University of Nebraska is a great tool. The University of Wisconsin has a nice app in N Price Calculator and the Saskatchewan Soil Conservation association (SSCA) has created a nice fertilizer blend app. Oklahoma State University has Ammonia Loss Calculator which uses soil pH and environmental conditions to estimate N losses from surface applied urea.

OSUNPK

I am also getting into the app game with two recently released apps the Canola Starter and Field Guide. Canola Starter provides a recommendation for safe starter rates based on row width and fertilizer source. Field Guide is app version of my Nutrient Management Field Guide, this app includes a nutrient removal calculator, nutrient deficiency ID tool, and fertilizer rate calculators. Along with these I have several in the wings with titles like Crop Nutrients in Irrigation, GDDs>0, and Wildlife FoodPlot.

ID Tools

As mentioned in my first two blogs the University of Missouri’s IDWeeds app was the first taxonomy based weed identification tool. I still use it regularly but both BASF and Monsanto have brought products to the table, both named WeedID, that are very user friendly and effective. Plant Images ($5.00) is a library of nutrient deficiency photos from a large selection of crops. Years and Ag PhDs also have apps available with deficiency images named Yara Checkit and Crop Nutrient Deficiencies. Cereal Disease ID app by BASF is intended for the UK and DuPonts Pestbook for Australian cotton farmers but I find that both can be very useful even in Oklahoma.

Pay to Play, Registrations

I have heard several good things about many of these apps. However they reguire the user to either be an employee or patron of the company or online registration. In a pay to pay app I would expect an all inclusive tool that could replace several free apps and preform record keeping duties.

Records

To be honest this is not a section I use much as I do not have an operation to maintain records on. However just by walking through the apps Crop Calculator by the University of Wisconsin and Pesticide Recordkeeping (PeRK) by University of Nebraska.

Scouting/Mapping

This section has apps that I classify as decision aid tools that could be used by someone scouting crops and apps that can be used to map and or collect field notes. South Dakota State has two great tools in Soy Diseases and NPIPM Soybean Guide. Scout and Sirrus.

Seed Select

Company based, Pioneers app products are some of the best with Plantability and Estimator

Sprayer Chemical

Some things haven’t changed I still use Tank Mix Calc and Spray Select on a very regular basis. But over the past year a few companies have added product finders and Clemson University has released a very nice sprayer calibration app named Calibrate.

Weather

The last two apps are Mesonet and Climate Corp Basic. You will notice the background on the screen shot is slightly different. That is because neither of these apps is kept Ina folder, both are on my home screen. Whether it is rain, temp, or wind weather impacts all aspects of agriculture therefore these two apps are always within one tap. For any producer in Oklahoma the Mesonet is an amazing system with 120 automated weather stations spread evenly across the state. This app just provides this data with just a few swipes of the finger. For those outside of Ok Climate Basic allows producers to first save field of interest and then monitor rainfall and environmental conditions of each field. While not extremely accurate it is defiantly close enough for those with a wide territory to be a very handy app.

For more information and some screen shots of the apps in action either visit my website http://npk.okstate.edu/presentations or my YouTube site http://www.youtube.com/osunpk under the playlist OSU_NPK on Sunup.

Nutrient Products: Stabilizers, Enhancers, Safeners, Biologicals and so on.

In this blog I am not going to tell you what to use or what not to use. In fact I will not mention a single product name. What I will do is hopefully provide some food for thought, new knowledge and direction.

First I want to approach a topic I have been called out on several times. I believe there is a stigma that University researchers and extension specialists do not want products to work. It may seem that way at times but it is far from the truth. The reality is that all of us are scientists and know someone may be inventing the product that changes nutrient management as we speak. The issue is that most of us have been jaded. While I may be younger I have over 11 years experience, testing “products” in the field, and that includes dozens of products. I have sprayed, spread, tossed, drilled, mixed and applied everything under the sun, with hopes that I will see that one thing I am always looking for, MORE GRAIN…

The truth is Everything works Sometimes yet Nothing works ALL the time. I and others in my profession do not expect anything to work 100% of the time, I am personally looking for something that will provide a checkmark in the win column 50% of the time. A win is the result of one of two things, more money in the producers pocket or less nutrients in the water or air. Products can increase vigor, nutrient uptake, chlorophyll concentration, greenness but not yield. What Co-op or elevator pays for any of those attributes? Grain makes green.

So many safeners, stabilizers, enhancers, biologicals, and on and on are available, so what should a producer do? Here are few things to think about. Ask yourself “ what part of my nutrient management plan can I get the most bang from improving”?

If the answer is Nitrogen (N) there are three basic categories: Urease inhibition, Nitrification inhibitor, and slow release. All are methods of preventing loss; the last two are preventing loss from water movement.

Urease inhibitors prevent the conversion of Urea to NH3 (ammonia). This conversion is typically a good thing, unless it happens out in the open. Ideally any urea containing product is incorporated with tillage or rain. However, in No-till when urea is broadcast and no significant rainfall events (>0.5”) occur, N loss is likely. The urea prill starts dissolving in the presence of moisture, this can be a light rain or dew, and urease starts converting urea into NH3. As the system dries and the day warms, if there was not enough moisture to move the NH3 into the soil the wind will drive NH3 into the atmosphere. Nitrogen loss via this pathway can range from 5% to 40% of the total N applied.

Urea placed on a wet soil under two different temperatures. Number in white is hours after application.

Urea placed on a dry soil, on top no water added, bottom left is moisture from the subsurface, and bottom right is simulated rain fall of 1/2″. Number in white is hours after application.

Nitrification inhibitors prevent the conversion of NH4 into NO3. Both are plant available N sources but NH4 is a positively charged compound that will form a bound with the negatively charged soil particles. Nitrate (NO3) is negatively charged and will flow with the water, in corn country that tends to be right down the tile drainage. Nitrate will also be converted to gasses under wet water logged soil conditions. Nitrate is lost in the presence of water, this means I do not typically recommend nitrification inhibitors for western OK, KS, TX dryland wheat producers.

Slow release N (SRN) comes in a range of forms: coated, long chain polymer, organic and many versions in each category. Again, water is the reason for the use of SRN sources. Slow release N whether coated or other have specific release patterns which are controlled by moisture, temperature and sometimes microbes. The release patterns of SRNS are not the same and may not work across crops and landscapes. For instance in Oklahoma the uptake pattern of nutrients for dryland corn in the North East is not that same as irrigated corn in the West. The little nuances in the growth pattern of a crop can make or break your SRN.

While N products have been on the market for decade’s phosphorus enhancers and stabilizers are relatively new, resulting in many of my peers holding back on providing recommendations until field trials could be conducted. At this point many of us do have a better understanding of what’s available and are able to provide our regional recommendations. Phosphorus products are not sold to prevent loss like their N counterparts; they are sold to make the applied P more available. On a scale of 1 to 10, P reactivity with other elements in the soil is a 9.9. If there is available Ca, Mg, Fe, or Al, phosphorus is reacting with it. In the southern Great Plains it is not uncommon for a soil to have 3,000-5,000 lbs of available Ca, a soil with a pH of 4, yes we have many of those, will have approximately 64,000 lbs of Al in the soil solution. That’s a lot of competition for your fertilizer P and for any substance that is trying to protect it.

I have been testing “biologicals” of all shapes and forms since 2003. While I have not hit any homeruns I have learned quite a bit. Many of these products originate from up north where the weather is kind and organic matter (OM) is high. Where I work the average OM is 0.75% and soil temp is brutal and unforgiving. Our soil does not have many reserves to release nor is it hospitable to foreign bodies.

Soil temperature for Stillwater OK under sod and bare soil conditions. Graph from http://www.Mesonet.org.

I hope you are still hanging on as this next topic is a bit of a soap box for me. Rate, Rate, Rate this aspect is missed both by producers and academia and it drives me crazy. If your crop is sufficient in any growth factor adding more will not increase yield. It goes back to Von Liebig’s LAW of the Minimum. I see too many research studies in which products are tested at optimum fertilization levels. This is just not a fair comparison. On the other hand, time and again I see producers sold on a product because they applied 30% less N or P and cut the same yield. If you let me hand pick 100 farms in Oklahoma I could reduce the N rate by 30% of the average and not lose a bushel on 75 of the farms. Why? Because the rate being used was above optimum in the first place, there is no magic just good agronomy. The list of products that increase the availability of nutrients is a mile long. Increasing nutrient availability is all well and good if you have a deficiency of one of those nutrients. If you don’t, well you have increased the availability of something you did not need in the first place.

University researchers and extension professionals seem to live and die by the statistics, and are told so regularly. We do rely upon the significant differences, LSD’s, and etc to help us understand the likely hood of a treatment causing an effect. However if I see a trend develop, or not develop, over time and landscape regardless of stats I will have no problem making recommendations. The stats help me when I do not have enough information (replications).

Too wrap up, have a goal. Do not just buy a product because of advertised promises or because a friend sells it. There is a right time and place for most of the things out there, but you need to know what that is and if it suits your needs. I also recommend turning to your local Extension office. We do our best to provide unbiased information in hopes of making your operation as sustainable as possible. If you are looking at making sizable investments do some reading, more than just Google. Testimonies are great but should but should not be enough to cut a check. Google Scholar www.google.com/scholar is a good resource for scientific pubs. I have done my best to put together a list of peer reviewed publications and their outcomes. To make the review work I had to be very general about outcome of the research. Either the product increased yield or decreased environmental losses or it had no impact. This was not easy as many of the papers summarize multiple studies. I did my best to make an unbiased recommendation but some could be argued. http://npk.okstate.edu/Trials/products/Product_Peer_Review.8-21-2014.pdf

2013 Wheat and Canola preplant soil test results

Every few years I request the results of all soil samples submitted to OSU Soil, Water, & Forage Analytical Labs (www.soiltesting.okstate.edu) under the crop codes of winter wheat and winter canola. Within this data set I can look at trends occurring across the state over time. In this report I will focus on the 2013 results but make some comparison with the 2011 sample values.

As it pertains to mobile nutrients such as N, S, and B there is little that can be applied from the previous year’s soil samples because their levels in the soil change rapidly. Samples must be collected every year to determine the current status. However the soil test levels of immobile nutrients, P, K, Mg, ect are relatively stable over time and the recommendation is to take a close look at these values every three to five years.

In 2013 the number of sample submitted increase. There were nearly 1000 more wheat soil samples (2733 to 3574) and 200 more canola soil samples (33 to 231). If the distribution of nutrient levels of the two years are compared the only significant change is that the soil test NO3 level was significantly lower in 2013 (Tables 1 and 2). This is attributed to the extremely dry 2012 spring and summer which delayed the breakdown of wheat straw and immobilization of residual N.

Table 1 and 2. Summary from all samples submitted to SWFAL under the wheat and canola crop codes in 2001 and 2013.

Reviewing the 2013 values the most concerning aspect is that 72% of the 3800+ soils samples had a Mehlich 3 P value below optimum soil test phosphorus (STP) of 65 (Figures 1 and 2). That adds up to 109,000 acres needing phosphorus, if you assume each sample represents 40 acres. There is no way to determine how much P2O5 if any was applied to these particular fields. However, an estimated impact of not fertilizing can be calculated. Based on the Oklahoma typical average yield of just below 40 bpa, it would cost the state approximately 575,000 bushels if the land went unfertilized. At $5.00 a bushel that is $2.8 million in revenue. To remedy the low STP it would take approximately 2.76 million lbs P2O5 at a cost of $1.5 million ($0.50 per lb).

In the NPKS response study wheat fields across the state were evaluated for a response to additional (in addition to producer’s standard practice) nitrogen, phosphorus, potassium, and sulfur. Phosphorus was the most limiting nutrient at 7 of the 59 harvest locations. A response to P occurred more often than any of the other nutrients tested. It is important to note at all seven fields had been fertilized with P that season, however each time it was below the OSU recommended rate. The response study was a great reminder that it is important to have a good soil test and to follow the recommendations.

Figures 1 and 2. 1)Range of soil test P levels (Mehlich 3) for all samples submitted to SWFAL in 2013 under the wheat and canola crop codes. 2) Range of Soil Test P level for all samples with STP<65.

Soil pH on the other hand showed a slight improvement from 2011. The percent of samples under 5.5 decreased by 4%, 25 to 21. Of the samples <5.5 the majority fall within the 5.0-5.5 category, which for winter wheat is still within the optimum growth window (Figures 3 and 4). These numbers are a good sign however two points should be made. There is a significant amount of winter wheat acres that is not sampled; much of this is likely to fall below 5.5 soil pH.

Figures 3 and 4. 1)Range of soil pH levels for all samples submitted to SWFAL in 2013 under the wheat and canola crop codes. 2) Range of soil pH levels for all samples with pH<5.5.

Additionally grid soil sampling and variable rate lime should consider on any field which the composite soil sample pH ranges from the high 4’s to the high 5’s. For example a 75 ac field near Deer Creek had a composite soil sample test pH of 5.3 and buffer index of 6.5. The OSU lime recommendation, for a wheat crop, was 2.2 ton per acre for a total of 166 tons to lime the entire field. However the producer grid soil sampled the field himself at a 2.5 acre resolution (31 samples). Figure 5, shows that the pH of the field ranged from 4.4 to 7.9. Only 33 tons of lime would be required if the field were limed using a variable rate technologies. Cutting the total amount applied by 133 tons would save the producer approximately $4000.

Oklahoma wheat and canola producers must take advantage of the weather when it goes their way. Yet if the crop does not have the proper soil pH and nutrients under it, it will never reach its potential. Take the time to collect a soil sample and send it in to a lab. The hour it takes to collect the sample a few dollars you spend on analysis will help ensure that crop you are producing has the best chance of hitting maximum yield in the most economically and environmentally sound manner.

Related Factsheets

OSU Soil Test Interpretations

http://npk.okstate.edu/documentation/factsheets/PSS-2225web2013.pdf

Fertilization Based on Sufficiency, Build-up and Maintenance Concepts

http://npk.okstate.edu/documentation/factsheets/PSS-2266web.pdf

2014 Harvest has wrapped up.

The last of the Precision Nutrient Management winter crop harvest was wrapped up in Chickasha June 25. Across the trial locations (Lahoma, Perkins, Chickasha, and Stillwater) the yields came in across the board in the high teens low twenties, bushel per acre. For most of the trials there was very little treatment difference, often the check ( Zero N) was not far from the fertilized plots. At this time the students are processing the grain. Some will be sent to a NIR Spectrophotometer for protein analysis the rest will be ground and analyzed for nitrogen and mineral content. The response to fertilizer was so low this year many of my trial areas have a double crop sorghum growing, in hopes to take advantage of the recent rains and harvest the residual nutrients. While I am processing the data and the students are running the samples I thought I would share a few of the images from the 2014 harvest. I will post results on the npk.okstate.edu as the become available and share the information on this blog. The best way to learn when results are posted are to follow me on Twitter @OSU_NPK or subscribe to our Extension news list serve (send me an email at b.arnall@okstate.edu to be added to the listserv).

In this you can see the impact of fertility on freeze damage. The dark plots survived the freeze, the light did not and were full of smaller tiller heads. In the end no major yield differences.