Home » Canola Trials

Category Archives: Canola Trials

Check Canola for Aphids

Tom A. Royer, Extension Entomologist

I have received scattered reports of cabbage aphids infesting canola racemes and low levels of green peach aphids feeding on canola leaves. Cabbage aphids are small, 2.0-2.5 mm (1/12 inches) blue-gray aphids with short cornicles. They are usually covered with a powdery wax coating. They are often found clustering on the developing panicle (Figure 1). They can cause plant stunting, distortion of growth, and flower abortion.

Cabbage Aphids

Green peach aphids are pale green to yellow (and sometimes pink) with long cornicles and antennae and measure 1/8 inch. They are found in winter and spring on leaves (Figure 2). Their feeding can cause stunting and defoliation. They can also transmit plant disease-causing viruses such as cauliflower mosaic and turnip mosaic viruses.

Green Peach Aphids

Scout for aphids by looking on the underside of the leaves, and racemes. For cabbage aphids, research conducted in Australia suggests that an insecticide application is justified if 20% of the racemes are infested with cabbage aphids.

For green peach aphids, research conducted by Dr. Kris Giles at OSU found that and average of one green peach aphid per plant can reduce seed yield by about 0.5 lb per acre. Thus, if the cost of an application is $10 per acre, and canola is bringing $0.2 per pound (quote from ADM Farmer Services 04/08/2016 www.adm.com), an infestation of 100 aphids per plant would cause yield loss of $10.00 (50 lb, x $0.2/pound) which is equal to the cost of the application. This is known as the ECONOMIC INJURY LEVEL (EIL). We typically set the ECONOMIC THRESHOLD (ET) below the EIL, in this case at 80% of the EIL (80 aphids per plant) to give time to schedule an application before the EIL is reached. Below is a set of suggested ECONOMIC THRESHOLDS, based on the cost of the application.

Application Cost Economic Injury Level Economic Threshold (Application cost/

0.5 lb/aphid x $0.2/lb (0.8 x EIL)

$8.00/acre 80 aphids/plant 64 aphids/plant\

$10.00/acre 100 aphids/plant 80 aphids/plant

$12.00/acre 120 aphids/plant 98 aphids/plant

$14.00/acre 140 aphids/plant 112 aphids/plant

Current recommendations for control of aphids in canola are listed in CR-7667, Management of Insect and Mite Pests in Canola which can be obtained online at http://pods.dasnr.okstate.edu/docushare/dsweb/Get/Document-3045/CR-7667web2009.pdf.

Transform® insecticide is no longer registered for use in canola as of November 11, 2015. Only existing stocks that have already been purchased and delivered to the grower before the cancellation can be applied according to the label.

Remember, green peach aphids have a history of developing resistance to pyrethroids, which are the primary registered insecticides for use in canola. Thorough coverage of an insecticide application is necessary to obtain optimal control.

If you notice natural enemy activity, especially lady beetles, and want to preserve their activity, keep several things in mind. Our research shows that Beleaf® insecticide is particularly benign to natural enemies because of its slow acting efficacy on aphids, which allows aphid-feeding beneficials to continue to eat them with little to no consequence on their biology. That being said, cabbage aphid may contain toxins that they acquire through their feeding which make them less palatable to some predators, and reduces their effectiveness as natural controls.

With all pesticides, review label restrictions for applications during bloom, as honeybees can be killed if exposed to several of the registered products. One registered product, Beleaf® (FMC Corporation) does not have any restrictions for application during bloom.

Canola fertilizer rates when skip row seeding.

When drilling canola a common strategy to improve seeding rate accuracy is to only use every other row which effectively doubles the rate of seed going through each meter. There are also many producers who utilize air seeders and just prefer the wider spacing. Every season I get several questions about determining total fertilizer rates if the seed is dropped every other row but fertilizer is dropped every row. Regardless of whether or not fertilizer goes down every row it is important that the amount of salts placed with seed does not exceed the limit. The table below provide the limits in terms of lbs of salt per acre. If using 18-46-0 (DAP) or 11-52-0 (MAP) this is equivalent to pounds of N per acre. However if the fertilizer you use contains potassium (K) or sulfur (S), those have to be considered. An easy rule of thumb for determining total salt level of a fertilizer is pounds of N + K + 1/2 S.

Maximum amount of salt that can be applied in furrow with canola seed. Application rate should be at or below this value.

In a scenario in which canola is seeded in skip rows but every row will get fertilizer the total amount of fertilizer can be doubled. For example on a 15″ row spacing the max salt rate is 5 lbs per acre. If you were using DAP as your starter that maximum rate to place in furrow would be 28 lbs of DAP per acre. If using a drill set of 7.5″ spacing and putting fertilizer down every row the max rate would increase up to 56 lbs DAP per acre.

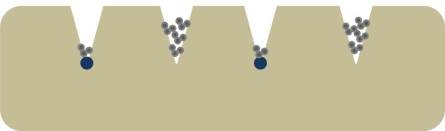

Seed, colored blue, is placed in every other row while an equal amount of fertilizer, dark grey circles, is placed in every row.

Some producers may have the capability of applying different rate in every other row. In this scenario it is important to maintain that safe rate in the seed furrow. In the opposite row, fertilizer rate can go as high as you wish or the equipment can handle.

Seed, colored blue, is placed in every other row while fertilizer, dark grey circles, is placed in every row. In this scenario a high rate is placed in the row without seed.

Now the big question is, “Is between row fertilization a good idea?” While we do not have results on this style of application (trials will be going out this year) we can draw upon upon similar work in other crops. For me the best win would be the second scenario in which a higher rate could be place between the rows. In this row I would use a urea and DAP blend. Any time we can put urea below the soil surface its a win and in fields with very soil soil test phosphorus (P) it would create something similar to the deep P bands once popular in corn production. Now if the field had adequate soil test P, I would focus on urea between rows. Keep in mind it is never a good to place urea in furrow with canola seed. For the average producer who is using a box drill the first scenario is the only option. In this case the rate of the between row bands will be reduced however I still believe on fields with very low soil test P this is potentially a great way to get the rest of it on. Remember if on 15″ and using DAP max rate only gets 12.9 lbs of P2O5 down. If fertilizer is dropped down every tube that number increases to about 26 lbs P2O5, which is still not enough for fields with low soil test P, but is better. With hope we will have some good results to share from the 2015-2016 canola crop.

Canola Planting Considerations.

Pre- and Early-Season Weed Management-

Dr. Angela Post- Small Grains Extension Weed Scientist

Winter canola is an excellent rotational partner with wheat. Integrating canola into a wheat system allows for the cleanup of weedy fields with primarily grassy weed problems. Conventional and Roundup Ready (RR) varieties are excellent choices for managing most grassy weeds including ALS-resistant populations, because grass-only herbicide options can be used in canola without crop injury. For specific grasses that are very difficult to control, like cereal rye and jointed goatgrass, it is advisable to use canola in year one of your rotation and Clearfield wheat in the second year of your rotation before going back to conventional wheat varieties. Due to sensitivity of canola, Clearfield wheat varieties should not be used the year prior to rotating into canola.

Canola planting time is just around the corner and many are going out now with preplant burndown applications. Remember that canola is sensitive to dicamba, 2,4-D, and MCPA and these products should not be used inside of 30 days before planting. Glyphosate, glufosinate and paraquat are all potential options for removing broadleaf weeds in no-till systems prior to planting. These products have no planting restriction for canola. Tillage is the best option to remove weeds in conventionally tilled systems.

It is important to consider your previous herbicide choices when planning for canola in the fall. Many herbicides used for spring weed control in wheat can limit rotation to winter canola. These include all Group 2 herbicides all of which have long rotation restrictions to canola, meaning you cannot plant canola in these fields for 18-24 months depending on the product. See Table 1 for a list of specific restrictions. If you have used one of these products in wheat in the spring, you must plant a canola variety with the SURT trait. Examples of varieties with this trait include: DKW 45-25, DKW 46-15, DKW 47-15, HyClass 115W, HyClass 125W. All of these varieties are also RR. Kansas State also has an open-pollinated non-RR variety called Sumner with the SURT trait for growers that prefer to grow conventional canola. Note that the SURT trait is not a genetically modified trait.

No additional in-season herbicide options have been added to the toolbox for winter canola growers in the upcoming season. Both trifluralin (Treflan) and ethalfluralin (Sonolan) can still be used as preemergent weed control options in canola in conventionally tilled systems. Both need to be mechanically worked into the ground and need an activating rainfall to work properly. Quizalofop (Assure II), sethoxydim (Poast), and clethodim (Select and many generics) are the grass control herbicides available for use in canola and can be used on any canola variety including RR varieties. Roundup Ready canola growers are allowed two applications of glyphosate at 22 oz/A each over the top of the emerged crop. Clopyralid (Stinger) is the only over-the-top broadleaf control option other than glyphosate. These weed control applications should be made early in the season between 2- and 6-leaf canola, and prior to bud formation, while weeds are still very small. Applications should be spaced at least 14 days apart. Early applications will eliminate fall weed competition with canola and protect yield. For more information or questions involving weed management in canola contact Extension Weed Specialist Angela Post at 405-744-9588 and follow @OSUWeedScience.

Table 1. Rotation restrictions for planting canola following wheat. For herbicides

applied in crops other than wheat please refer to the herbicide label.

1Minimum interval between herbicide application and seeding canola. Refer to full herbicide labels for specific information as geography, pH, and rainfall may affect this interval.

2Rotation restriction can be overcome with use of a SURT canola variety.

3Rotation intervals depend on geography.

4Rotation interval depends on herbicide rate.

Pre plant fertilizer concerns with Canola

Dr. Brian Arnall- Precision Nutrient Managment Extension Specialist

When it comes to pre-plant fertility issues with canola, I typically have two soap boxes. But at this point in the canola game we are behind in terms of getting soil samples collected or applying lime and getting a boost at emergence. So assuming pH is good and you know what your soil nutrient level is we can move on to planting. One thing that over the past seven or eight years keeps coming up is the importance of starter fertilizers and the rates and sources used. Getting that little canola plant off to a good start is extremely important however with that little bitty seed a little goes a long way.

The figure below shows the impact of DAP (18-46-0) placed in row, on relative canola stands, when canola was planted in 15” rows. At 5 lbs/A of N or 28 lbs/A of DAP, the canola stand is reduced to 75%. While this seems like a great loss, the compensating nature of canola and the fairly high seeding rates used, this is a manageable level. The benefits of the additional nitrogen and phosphorus applied with the seed also help out-weigh the loss of stand. The addition of the P near the germinating seed is vital. The phosphorus aids in early root and shoot growth, helping the crop to get off to a good start. In areas where soil pH is of concern the P near the young seedling will reduce aluminum toxicity and allow the plant to tolerate the low pH. Keep in mind, while banding P will help in acidic soils, canola is still very sensitive and will not tolerate the same low pH conditions as our winter wheat’s.

One very important factor to keep in mind is the impact of the critical rate and row spacing. The 5 lbs of N per acre critical level set for 15” row spacing is increased to 10 lbs on 7.5’s and cut to 2.5 lbs on 30’s. The change in rate is because we use lbs per acre. So if you apply the same amount of material per acre on a 15” spacing and a 30” spacing there is actually twice as much material in the 30” row. Table 1, shows the equivalent amount of N placed in row for popular row spacing’s.

Oklahoma State has released a smart phone app, available for both apple and android devices, to aid in determining maximum in-furrow rates. Canola Starter app provides guidelines based upon the nutrient concentrations of the fertilizers you plan to use. The final note on in-furrow fertilizer with Canola, avoid using urea. The likelihood of injury from the urea converting to ammonia greatly outweighs any potential benefits. For further information, comments, or questions please contact Dr. Brian Arnall Extension Precision Nutrient Specialist 405-744-1722 or following me on Twitter @OSU_NPK.

Canola Starter available on iOS and Android. For more information see http://www.dasnr.okstate.edu/apps.

Winter canola planting decisions:

Josh Lofton- Cropping Systems Specialist

Josh Bushong- Extension Associate

Stand establishment is one of the most critical practices in canola planting. This is not only because these stands are highly influential to end of the season yields but because getting the crop up with adequate growth will be critical to give the plants the best over-winter survivability possible. To accomplish this, growers need to make sure they make good field selection and follow good planting practices

Field Selection:

Soil nutrients are a critical aspect. Soil samples should be collected on a regular basis to ensure optimum productivity. Also, ensure recommendations for winter canola are followed, as nutrient recommendations for other crops may be invalid. For more information canola fertilizer management refer to the nutrient management section by Dr. Arnall.

Winter canola grows similar to winter wheat. Fields that can adequately produce wheat have the potential to produce canola. These include, well-drained soils with adequate soil nutrients. However, canola can be more sensitive than wheat. One aspect that canola can be more sensitive to is soil pH. While wheat can be grown in soils as low as 5.5 without significant yield loss, canola must be grown on soils with pHs above 5.8. In fact, canola is best grown in soils with soil pHs ranging from 6.0 to 7.0. Therefore, it is essential that if fields have lower pH, lime be applied with adequate time to neutralize the acidic soil pH before rotating into canola.

In addition to all the soil conditions, crop rotation should be considered prior to planting canola. One of the major hindrances in growing canola in rotation with other crops is herbicide carry-over. For detailed information regarding this aspect, refer to table 1 in the weed management section. To account for this, detailed field records should be kept and consulted before rotating with canola.

Planting Date:

Planting time depends on many aspects. Insured growers should plant within the constrained planting dates. For Oklahoma, the earliest planting date is September 10th with the latest date being October 10th. However, within these guidelines, seedbed and environmental conditions should be the driving factor to determine when to plant. The goal of these planting dates is to have the crop germinate, emerge, and establish 6-8 true leaves prior to the first killing freeze. As a general rule, the crop should be planted 4 to 6 weeks before this freeze. To achieve good establishment of the crop, canola should be planted into firm seedbed with adequate soil moisture. If canola is planted into dry soil (dusted in), the effective planting date will be delayed until adequate conditions for germination and emergence exist. In no-till systems, it is important to remember that canola emergence and growth will be slightly delayed. Therefore, if adequate conditions exist, no-till fields should be planted before similar conventionally tilled fields.

Uneven canola emergence. Canola on left emerged later and did not

have enough time to put on adequate growth (Photo courtesy of Josh

Bushong)

Planting depth, plant spacing, and seeding rate:

Since canola is a small seeded crop, shallow planting is required. For best germination and emergence, seeds should be planted between 0.5 and 1 inch. If adequate moisture is available deeper, planting depth can be increased. However, deeper planting has the potential to decrease germination, percent emergence, and early fall growth, so deeper planting should only be used when the planting condition advantage is present and only on certain soils. Therefore, caution should be used in planting deeper than 1 inch. Furthermore, even though moisture may be present deeper, seeds should not be planted deeper than 1.5 inches.

Oklahoma growers have options when deciding row spacing used for planting canola and depend on what equipment there is available and their production system. Since canola is typically rotated within a winter wheat production system, box drills and air seeders are typically widely available. Row-spacing for these can range from 6 to 15 inches. Row spacing within this range has little impact on final yields. As producers move from drills and air seeders to planters, row spacing typically increases from 15 up to 30 inches. All of the row-widths have the potential to produce adequate canola. Some, however, will be more beneficial than others. Narrow row spacing has the potential to result in early canopy closure, reduce potential weed competition, and may help reduce shatter prior to harvest (especially when direct harvested). Wider spacing, however, allows for some flexibility in specialized planter attachments used, especially row-cleaners, which can be greatly beneficial in no-till systems.

Seeding rates for canola in Oklahoma range from 1 to 5 lbs/A. However, row spacing plays a critical role on seeding rates. When canola is planted on less than 15 inch spacing, some flexibility exists for planting rates. Higher seeding rates can produce more uniform stands, uniform maturity, and thinner stalks that can greatly help harvest efficiency. Too high of stands can increase disease incidence, winterkill, and lodging. When row spacing is increased beyond 15 inches, care should be taken not to over seed. High seed populations can increase fall growth and potentially increase hypocotyl height, which in turn can lead to high winterkill. Optimum populations for this wider row spacing typically range from 2 to 3 lbs/A.

For further information, comments, or questions please contact Josh Lofton Extension Cropping Systems Specialist at 405-744-3389 or follow me on Twitter @OSU_oilseeds.

While producers have faced many challenges over the last couple of seasons in Oklahoma agriculture, the outlook for winter canola looks very promising for the upcoming season. Producers should focus on taking all of the right steps to ensure the 2015-2016 crop starts on the right foot and takes full advantage of the promising conditions this season. Good luck to everyone one on their upcoming production season and if anyone from Oklahoma State extension can help or assist in any way, please feel free to contact.

Some thoughts on pre-plant nitrogen and a little outside the box thinking

It is that time of year, every Co-op I drove by the other day had a line of trucks pulling anhydrous tanks and the spinner spreaders were being loaded. For those of you who haven’t applied your nitrogen yet lets discuss the options traditional and nontraditional.

Anhydrous Ammonia, 82-0-0: by far the most widely used N source is the southern Great Plains. While it is not the most enjoyable to work with it is the cheapest per pound of N and that leads to its wide spread use without Oklahoma wheat production. Just a few simple rules with NH3, get it in the ground and close the row behind you. In conventional till this is usually easier unless the ground is too wet or too dry. In no-till this may be a little more challenging but usually easily accomplished. With the rise in low disturbance applicators I am seeing more and more acres of no-till receiving NH3. Last year I was in a field of stripper stubble and I had a hard time finding where the rig had run, minus wheel tracks.

Urea, 46-0-0: is second on the hit list in nitrogen sales in our state. It is a safe source that is easily handled and applied. In a conventional till system where the urea can be worked in shortly after application it is a very efficient and effective source. Unfortunately when it is applied to the soil surface and rain is the method of incorporation we can experience between 5-60% N losses. The losses come from how urea is converted to plant available ammonium (NH4). For urea (NH2)2CO2, to be converted to plant available NH4 it needs the enzyme urease. Urease is present everywhere but in the highest concentrations on plant residue. The figure below shows the reaction, urease converts urea into NH3 as soon as the prill dissolves. In the presence of moisture the NH3 (gas) is turned immediately to NH4 (solid) and is absorbed onto the soil particle.

The problems come when there is no soil particle for the NH4 to bind with. It usually takes 0.50 inches of rain or irrigation to fully dissolve and incorporate urea into the soil. So if we only get a few tenths or hundredths, even heavy dews, some of the urea will dissolve, be converted to NH3 then NH4 and be left on the plant/residue. When the moisture dries, some or all of the NH4 goes back to NH3 and will gas off into the atmosphere. I have even seen this happen when urea is applied on a wet/damp soil, not incorporated and it doesn’t rain for significant period of time. If the temps are cooler the urease is slower so less of the urea is converted to NH4, but if the temps are warm 60+ degrees these little enzymes can act very quickly.

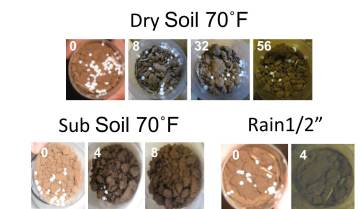

Urea placed on the surface of a wet soil under two temperature regimes. White text is the number of hours after application.

Urea placed on dry soil, Top row: dry soil no water added, Bottom left, moisture added from subsurface, Bottom right : simulated rain fall event of 1/2″. White text is the number of hours after application.

Below is a short video on using urea fertilizer.

While the recent rains are a blessing and will surely help germination, it is not aiding our N use efficiency especially in no-till. That is why in some parts of the state you may see some grain drills running right now. Some of those producers are not planting wheat they are actually applying there pre-plant urea. I have even been told in the SW part of the start some producers are using air-seeders to apply their urea. While this seems like a costly venture I have worked with the Ag Economist to create a calculator to figure up the break even for when it would pay to use an air-seeder over the traditional spinner spreader in no-till. We hope to put the finishing touches on it in the next few days. When it is completed it will be shared on this blog.

Liquid Urea Ammonium Nitrate, 32-0-0 or 28-0-0: while this is one of the more expensive forms of N many producers are utilizing this source because the can pre buy and store on site and as sprayer get larger they can cover a significant amount of ground quickly. For the most part UAN is used in no-till and is a great source. I always recommend that applicators use streamer nozzle or streamer bars to apply UAN. When UAN is applied via a flat fan nozzle it spreads the fertilizer across the residue allowing a significant portion to be tied up. The streamers concentrate the fertilizer into streams/bands reducing contact with residue and increasing the amount of UAN that reaches the soil surface.

Timing and Rates

The cost of anhydrous, about $0.1 to 0.12 less per pound N less than urea is driving its use this year. The lower price is also driving a significant about of producers to go with 100% of their N pre-plant. While this makes for sound economics now having all of your N upfront is like putting all of your eggs in one basket. If we do get that cold and wet winter as some are calling for this presents a great chance for the N to move down the soil profile and down the slope. I have always recommended split application. This allows a producer to judge the crop throughout fall, winter and even yearly spring and adjust his or her N plan accordingly. For those who plan to graze there is still a need to get enough N down to produce fall forage, this may be 50 to 80 lbs of N, but for grain only production planted later in the fall a typical crop may only need 20-30 lbs of N before going into winter. The old rules of thumb, 2 lbs N per bushel and 30 lbs N per 100 lbs of gain still work and are better than a guestimate but we have better ways. Right now is the time to plan to apply N-rich strip, a strip in the field with 40 to 50 lbs more than the rest of the field. These strips can be applied with a variety of applicators, but as long as the N goes down in at least an area 10 ft wide by 300 ft long it is good to go.

Just a few of the applicators used for putting out N-Rich Strips. ATV Sprayer, Receiver Hitch mounted Sprayer, Road sprayer with a rear boom, pull type spinner, large sprayer, push spreader. Not shown is NH3 applicator.

Below is a N-Rich Strip 101 video.

If you have got the N-Rich strips out you can set back and watch to see when and if they develop. If you can see the strip you know you need too fertilize.

While many are not ready to think about top-dressing yet, it is never too early. Don’t be afraid to think outside the box. Oklahoma’s springs tend to present the perfect conditions for N loss when urea is the primary N source. This year in a 4R Top-dress Nitrogen Application Demo, at Lahoma and Chickasha, we are going to apply just about every available commercial source in about every possible manor. Urea will be broadcast, coated with inhibitors, applied with a grain drill, NH3 will be knifed in, and UAN will be applied with flat fan nozzles, streamer nozzles and knifed in. As technologies improve and the cost of N remains relatively high the options for top-dress N application will continue to improve. The economics of wheat production don’t look great right now so don’t be afraid to think outside the box, even if it does raise the eyebrows of your neighbors. Fill free to contact myself or your local extension educator if you have any questions about N application.

Sampling for pH and liming in continuous no-till fields

This article is written by Dr. David Mengel, Kansas State University Soil Fertility Specialist.

One question that commonly comes up with continuous no-till operations is: “How deep should I sample soils for pH?” The next common question is: “How should the lime be applied if the soil is acidic and the field needs lime?”

Sampling depth in continuous no-till

First, sampling depth. Should two sets of samples be taken, at different depths?

Our standard recommendation for pH is to take one set of samples to a 6 inch depth. On continuous no-till fields where most or all of the nitrogen (N) is surface applied, we recommend taking a second sample to a 3-inch depth. We make the same recommendation for long-term pasture or grass hayfields, such as a bromegrass field that has been fertilized with urea annually for several years.

Nitrogen fertilizer is the primary driving force in lowering soil pH levels, so N application rates and methods must be considered when determining how deep to sample for pH. In no-till, the effects of N fertilizer on lowering pH are most pronounced in the area where the fertilizer is actually applied. In a tilled system, the applied N or acid produced through nitrification is mixed in through the action of tillage and distributed throughout the tilled area.

Where N sources such as urea or liquid UAN solutions are broadcast on the surface in no-till system, the pH effects of the acid formed by nitrification of the ammonium will be confined to the surface few inches of soil. Initially this may be just the top 1 to 2 inches but over time, and as N rates increase, the effect of acidity become more pronounced, and the pH drops at deeper depths. How deep and how quickly the acidity develops over time is primarily a function of N rate and soil CEC, or buffering capacity.

Where anhydrous ammonia is applied, or liquid UAN is knifed or coulter banded below the surface, an acid zone will develop deeper in the soil, usually 2-3 inches above the release point where the fertilizer is placed in the soil. So if the ammonia is injected 8 inches deep, there will be acid bands 5 to 8 inches below the soil surface. As with long-term surface applications, these bands will expand over time as more and more N fertilizer is placed in the same general area. The graphic below illustrates the effect of a high rate of ammonia placed in the same general area in the row middle on a high CEC soil for more than 20 years.

The actual depth of the acid zone in fields fertilized with ammonia gets tricky as application depth can vary depending on the tool used to apply the ammonia. Traditional shank applicators generally run 6 to 8 inches deep, so a sample for pH measurement could be taken at 3-6 inches or 5-8 inches deep, depending on how deep the shanks were run. The new low-disturbance applicators apply the ammonia 4-5 inches deep. A sweep plow or V-blade applies ammonia only 3-4 inches deep. So sampling depth for pH should really depend on where the acid-forming N fertilizer is put in the soil.

Liming application methods in continuous no-till

Now, where do you place the lime in continuous no-till? If you surface apply N, then surface apply the lime. That’s a simple but effective rule. But remember that surface-applied lime will likely only neutralize the acidity in the top 2-3 inches of soil. So if a producer hasn’t limed for 20 years of continuous no-till and has applied 100 to 150 pounds of N per year, there will probably be a 4-5 inch thick acid zone, and the bottom half of that zone may not be neutralized from surface-applied lime. So, if a producer is only able to neutralize the top 3 inches of a 5-inch deep surface zone of acid soil, would that suggest he needs to incorporate lime? Not really. Research has shown as long as the surface is in an appropriate range and the remainder of the acid soil is above pH 5, crops will do fine.

Liming benefits crop production in large part by reducing toxic aluminum, supplying calcium and magnesium, and enhancing the activity of some herbicides. Aluminum toxicity doesn’t occur until the soil pH is normally below 4.8. At that pH the Al in soil solution begins to increase dramatically as pH declines further. Aluminum is toxic to plant roots, and at worse the roots would not grow well in the remaining acid zone.

This implies that the acid zones from ammonia are probably not a major problem. We have monitored ammonia bands in the row middles of long-term no-till for many years and while the pH got very low, below 4.5, we never saw any adverse impacts on the crop that would justify liming and using tillage to incorporate the lime. In fact, some nutrients such as zinc, manganese, and iron can become more available at low pH, which can be an advantage at times.

Yield enhancement is not the only concern with low-pH soils, however. Herbicide effectiveness must also be considered. The most commonly used soil-applied herbicide impacted by pH is atrazine. As pH goes down, activity and hence performance goes down. So in acid soils weed control may be impacted. We do see that in corn and sorghum production.

Liming products for no-till

When choosing a liming product, is there any value to using dolomitic lime (which contains a large percentage of magnesium in addition to calcium) over a purely calcium-based lime product? On most of our soils in Kansas we are blessed with high magnesium content. So as long as we maintain a reasonable soil pH, there normally is enough magnesium present to supply the needs of a crop. Calcium content is normally significantly higher than magnesium, so calcium deficiency is very, very rare in Kansas. The soil pH would need to be below 4.5 before calcium deficiency would become an issue. Before calcium deficiency would occur, aluminum toxicity or manganese toxicity would be severely impacting crop growth. So producers really don’t have to worry about a deficiency of calcium or magnesium on most Kansas soils.

What about the use of pelletized lime as a pH management tool on no-till fields? The idea has been around for a while to use pel-lime in low doses to neutralize the acidity created from nitrogen and prevent acid zones from developing. There is no reason it won’t work, if you apply enough product each year. Pel-lime is a very high-quality product, normally having 1800 to 2000 pounds of effective calcium carbonate (ECC) per ton, and can be blended with fertilizers such as MAP or DAP or potash easily.

But it is costly. As an example, at a cost of $160 per ton and 1,800 lbs effective calcium carbonate (ECC) per ton, 100 pounds of ECC pel-lime costs $8.80. If it costs $25 per ton to buy, haul, and apply a 50% ECC limestone, that equates to $2.50 per 100 pounds ECC.

If you were applying 100 pounds of urea-based nitrogen, it would take approximately 180 pounds of ECC to neutralize the acidity produced by the N. This would require 200 pounds of 1,800 pound ECC pel-lime or 360 pounds of 50% ECC ag lime. The cost would be around $16 per acre with pel-lime or $4.50 per acre with ag lime. So technically, the pel-lime option is fine. But it would cost more than 3 times as much, at least in this example. You can use your own figures regarding costs and ECC of different lime products available to you to do a similar calculation. Deciding which product to use is a simple economic choice.

Summary

Applying N fertilizer to soil will cause the soil to become acidic over time. Placement of the applied N and the level of soil mixing done through tillage determine where the acid zones will develop. Make sure your soil testing program is focused on the area in the soil becoming acidic, and apply the lime accordingly.

Dave Mengel

Kansas State University

Professor Soil Fertility Specialist

dmengel@ksu.edu

2013 Wheat and Canola preplant soil test results

Every few years I request the results of all soil samples submitted to OSU Soil, Water, & Forage Analytical Labs (www.soiltesting.okstate.edu) under the crop codes of winter wheat and winter canola. Within this data set I can look at trends occurring across the state over time. In this report I will focus on the 2013 results but make some comparison with the 2011 sample values.

As it pertains to mobile nutrients such as N, S, and B there is little that can be applied from the previous year’s soil samples because their levels in the soil change rapidly. Samples must be collected every year to determine the current status. However the soil test levels of immobile nutrients, P, K, Mg, ect are relatively stable over time and the recommendation is to take a close look at these values every three to five years.

In 2013 the number of sample submitted increase. There were nearly 1000 more wheat soil samples (2733 to 3574) and 200 more canola soil samples (33 to 231). If the distribution of nutrient levels of the two years are compared the only significant change is that the soil test NO3 level was significantly lower in 2013 (Tables 1 and 2). This is attributed to the extremely dry 2012 spring and summer which delayed the breakdown of wheat straw and immobilization of residual N.

Table 1 and 2. Summary from all samples submitted to SWFAL under the wheat and canola crop codes in 2001 and 2013.

Reviewing the 2013 values the most concerning aspect is that 72% of the 3800+ soils samples had a Mehlich 3 P value below optimum soil test phosphorus (STP) of 65 (Figures 1 and 2). That adds up to 109,000 acres needing phosphorus, if you assume each sample represents 40 acres. There is no way to determine how much P2O5 if any was applied to these particular fields. However, an estimated impact of not fertilizing can be calculated. Based on the Oklahoma typical average yield of just below 40 bpa, it would cost the state approximately 575,000 bushels if the land went unfertilized. At $5.00 a bushel that is $2.8 million in revenue. To remedy the low STP it would take approximately 2.76 million lbs P2O5 at a cost of $1.5 million ($0.50 per lb).

In the NPKS response study wheat fields across the state were evaluated for a response to additional (in addition to producer’s standard practice) nitrogen, phosphorus, potassium, and sulfur. Phosphorus was the most limiting nutrient at 7 of the 59 harvest locations. A response to P occurred more often than any of the other nutrients tested. It is important to note at all seven fields had been fertilized with P that season, however each time it was below the OSU recommended rate. The response study was a great reminder that it is important to have a good soil test and to follow the recommendations.

Figures 1 and 2. 1)Range of soil test P levels (Mehlich 3) for all samples submitted to SWFAL in 2013 under the wheat and canola crop codes. 2) Range of Soil Test P level for all samples with STP<65.

Soil pH on the other hand showed a slight improvement from 2011. The percent of samples under 5.5 decreased by 4%, 25 to 21. Of the samples <5.5 the majority fall within the 5.0-5.5 category, which for winter wheat is still within the optimum growth window (Figures 3 and 4). These numbers are a good sign however two points should be made. There is a significant amount of winter wheat acres that is not sampled; much of this is likely to fall below 5.5 soil pH.

Figures 3 and 4. 1)Range of soil pH levels for all samples submitted to SWFAL in 2013 under the wheat and canola crop codes. 2) Range of soil pH levels for all samples with pH<5.5.

Additionally grid soil sampling and variable rate lime should consider on any field which the composite soil sample pH ranges from the high 4’s to the high 5’s. For example a 75 ac field near Deer Creek had a composite soil sample test pH of 5.3 and buffer index of 6.5. The OSU lime recommendation, for a wheat crop, was 2.2 ton per acre for a total of 166 tons to lime the entire field. However the producer grid soil sampled the field himself at a 2.5 acre resolution (31 samples). Figure 5, shows that the pH of the field ranged from 4.4 to 7.9. Only 33 tons of lime would be required if the field were limed using a variable rate technologies. Cutting the total amount applied by 133 tons would save the producer approximately $4000.

Oklahoma wheat and canola producers must take advantage of the weather when it goes their way. Yet if the crop does not have the proper soil pH and nutrients under it, it will never reach its potential. Take the time to collect a soil sample and send it in to a lab. The hour it takes to collect the sample a few dollars you spend on analysis will help ensure that crop you are producing has the best chance of hitting maximum yield in the most economically and environmentally sound manner.

Related Factsheets

OSU Soil Test Interpretations

http://npk.okstate.edu/documentation/factsheets/PSS-2225web2013.pdf

Fertilization Based on Sufficiency, Build-up and Maintenance Concepts

http://npk.okstate.edu/documentation/factsheets/PSS-2266web.pdf

Placing Fertilizer with Canola at planting has positives and negatives.

With all things holding constant the last canola trials of our project should be picked up by the plot combine Thursday 6-20-13. Before the first yield results comes to my desk I can tell you that we are learning a great deal from the trials this year. In particular the DAP (18-46-0) placed with seed trail that was supported by the Oklahoma Oilseed Commission. This past year at the no-till site in Perkins, which has a low soil pH, the check plots that did not receive any fertilizer, preplant or banded, did not survive the winter. Additionally at both of our locations, Lahoma (low soil test P) and Perkins, we have documented that oil content was reduced when phosphorus was left out of the treatment.

Additionally out of the four site years, that is two locations over two years, the addition of DAP with the seed in-row reduced stand. The graph below shows just how much stand was reduced on a relative basis. Relative stand is a way to compare the DAP treated to the Check (no DAP) which we assume is 100%. So if we look at the graph below the plots were at 75% relative stand (i.e. 25% loss) at approx 5 lbs N per ac. By about 15 lbs N the stand was down to 50%.

There are a few things to keep in mind first, in the case of these trials stand loss did not always mean yield loss. Canola is a great compensatory crop, if there is open space it will grow into it. I will have to run the final yield data to get more answers. These trials were planted on 15″ rows putting down 5 lbs seed per ac, or at least that was the target rate. Many have shown that the seeding rate does not have to be that high if sown properly. I believe in a few cases we may have actually benefited from thinning the stand. However if you were planting 2.5 lbs seed per acre a small loss of stand may be a bigger yield loss. This is one of the question we will have to answer in the future.

And finally it should be noted that canola is planted on a wide range of spaces 6″,7.5″, 12″, 15″, 30″ are some of the most common. As the row width changes the amount of N placed with the seed changes. In other words if the goal is 50 lbs DAP per acre you will put twice as much in a 15″ row than you do a 7.5″ row. The Table at the bottom provide a guide for equivalent rate based on 15″ rows. For example if your target a excepted stand loss of 25% (5 lbs N according to the Figure) but you are planting on 6″ row spacing the recommendation would be apply no more than 13 lbs N per ac in the row or 72 lbs DAP/ac (13/.18)