Home » Posts tagged 'top-dress'

Tag Archives: top-dress

One Well-Timed Shot: Rethinking Split Nitrogen Applications in Wheat production

Brian Arnall, Precision Nutrient Management Specialist

Samson Abiola, PNM Ph.D. Student.

Nitrogen is the most yield limiting nutrient in wheat production, but it’s also the most unpredictable. Apply it too early, and you risk losing it to leaching or volatilization before your crop can use it. Apply it too late, and your wheat has already determined its yield potential; you’re just feeding protein at that point. For decades, the conventional wisdom has been to split nitrogen applications: put some down early to get the crop going, then come back later to apply again. But does splitting actually work? And more importantly, when is the optimal window to apply nitrogen if you want to maximize both yield and protein quality? We spent three years across different Oklahoma locations testing every timing scenario to answer these questions.

How We Tested Every Nitrogen Timing Scenario in Oklahoma Wheat

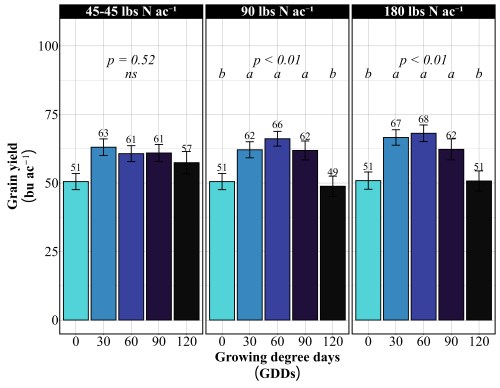

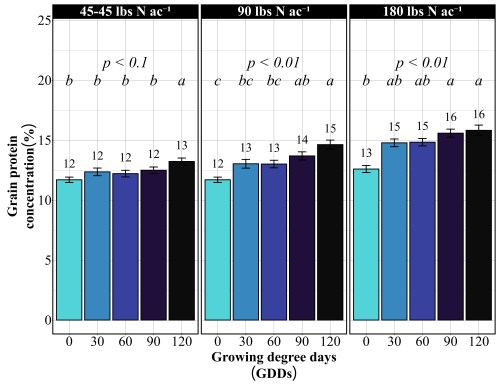

Between 2018 to 2021, we conducted field trials at three Oklahoma locations, including Perkins, Lake Carl Blackwell, and Chickasha, representing different soil types and growing conditions across the state. We tested three nitrogen rates: 0, 90, and 180 lbs N/ac, applied as urea at five critical growth stages based on growing degree days (GDD). These timings were 0 GDD (preplant, before green-up), 30 GDD (early tillering), 60 GDD (active tillering), 90 GDD (late tillering, approximately Feekes 5-6), and 120 GDD (stem elongation, approaching jointing). We also compared single applications at each timing against split applications, where half the nitrogen (45 lbs N ac-1) went down preplant, and the other half was applied in-season (45 lbs N ac-1).

The Sweet Spot: Yield and Protein at the 90 lbs N/ac Rate

Across all site-years, at the 90 lbs N/ac rate, timing had a significant impact on both yield and protein. The highest yields came from the 30 and 90 GDD timings, producing 62 to 66 bu/ac, with 60 GDD reaching the peak (Figure 1). Protein at these early timings stayed relatively modest at 13%. The 90 GDD timing delivered 62 bu/ac with 14% protein matching the yield of the 30 GDD application but pushing protein a percentage higher (Figure 2). The real problem appeared at 120 GDD. Delaying application until stem elongation dropped yields to just 49 bu/ac, even though protein climbed to 15%. That’s a 13 bushel penalty compared to the 90 GDD timing. At current wheat prices per bushel, that late application may cost farmers over $100 per acre in lost revenue. By 120 GDD, the crop has already determined its yield potential tillers are set, head numbers are locked in and nitrogen applied at this stage can only be directed toward protein synthesis, not building more yield components.

More Nitrogen Does not lead to high yield

Doubling the nitrogen rate to 180 lbs N/ac revealed something critical, more nitrogen doesn’t mean more yield. The yield pattern remained nearly identical to the 90 lbs N/ac rate. The 60 GDD timing produced the highest yield at 68 bu/ac, followed closely by 30 GDD at 67 bu/ac. The 90 GDD timing yielded 62 bu/ac, and the 120 GDD timing again crashed to 51 bu/ac. The only difference between the two rates was protein concentration (Figure 2). At 180 lbs N/ac, protein levels increased across all timings: 13% at preplant, 15% at both 30 and 60 GDD, 15-16% at 90 GDD, and 16% at 120 GDD. This confirms a fundamental principle: once farmers supply enough nitrogen to maximize yield potential, which occurred at 90 lbs N/ac in these trials, additional nitrogen only increases grain protein. It does not build more bushels. Unless farmers are receiving premium payments for high-protein wheat, that extra 90 lbs of nitrogen represents a cost with no yield return.

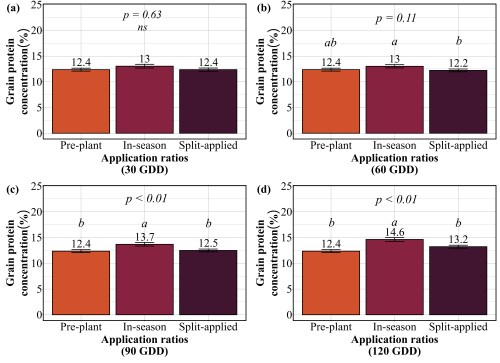

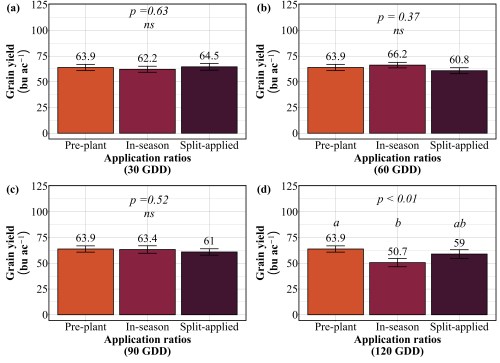

Should farmers split their nitrogen application?

Now that timing has been established as critical, the next question becomes: should farmers split their nitrogen applications, or is a single application sufficient? The conventional recommendation has been to split nitrogen apply part preplant to support early growth and tillering, then return with a second application later in the season to boost protein and finish the crop. But does the data support this practice? We compared three strategies at each timing: applying all nitrogen preplant, applying all nitrogen in-season at the target timing, or splitting nitrogen equally between preplant and in-season timing. The goal was to determine whether the extra trip across the field will deliver better results.

Our findings revealed that splitting provided no consistent advantage. At 30 GDD, all three strategies preplant, in-season, and split performed identically, producing 62-65 bu/ac with 12-13% protein (Figure 3 and 4). No statistical differences existed among them. At 60 GDD, similar pattern was held. Yields ranged from 61 to 66 bu/ac and protein stayed at 12-13% regardless of whether farmers applied all nitrogen preplant, all at 60 GDD, or split between the two. At 90 GDD, the single in-season application actually outperformed the split. While yields remained similar across all three methods (61-64 bu/ac), the in-season application delivered significantly higher protein at 13.7% compared to 12.4% for preplant and 12.5% for split applications. This suggests that concentrating nitrogen at 90 GDD, rather than diluting it across two applications, allows more efficient incorporation into grain protein. The only timing where splits appeared beneficial was 120 GDD, where the split application yielded 59 bu/ac compared to 51 bu/ac for the single late application. But this is not a win for splitting, it simply demonstrates that applying all nitrogen at 120 GDD is too late and putting half down earlier salvages some of the yield loss. Across all timings tested, splitting nitrogen into two applications offered no agronomic advantage over a single well-timed application, meaning farmers are making an extra pass for no gain in yield or protein.

Practical Recommendations for Nitrogen Management

Based on three years of field data, farmers should target the 90 GDD timing (late tillering, Feekes 5-6) for their main nitrogen application to achieve the best balance between yield and protein. This window typically falls in late February to early March in Oklahoma, though farmers should monitor crop development rather than relying solely on the calendar apply when wheat shows multiple tillers, good green color, and vigorous growth. A rate of 90 lbs N/ac maximized yield in these trials; higher rates only increased protein without adding bushels, so farmers should only exceed this rate if receiving premium payments for high-protein wheat. Splitting nitrogen applications provided no advantage at any timing, meaning a single well-timed application at 90 GDD is sufficient for most Oklahoma wheat production systems. The exception would be sandy soils with high leaching potential, where splitting may reduce nitrogen loss. Farmers should avoid delaying applications until 120 GDD or later, as this timing consistently resulted in 15-25 bushel per acre yield losses even though protein increased. For farmers specifically targeting premium protein markets, a two-step strategy works best: apply 90 lbs N/ac at 90 GDD to establish yield potential and baseline protein, then follow with a foliar application of 20-30 lbs N/ac at flowering to push protein above 14% without sacrificing yield. Finally, weather conditions matter hot, dry forecasts increase volatilization risk and reduce uptake efficiency, so farmers should consider moving applications earlier if low humidity conditions are expected.

Split Application Caveat * Note from Arnall.

The caveat to the it only takes one pass, is high yielding >85+ bpa, environments. In these situation I still have not found any value for preplant nitrogen application. I have seen however a split spring application is valuable. Basically putting on 30-50 lbs at green-up, with the rest following at jointing (hollowstem). The method tends to reduce lodging in the high yielding environments.

This work was published in Front Plant Sci. 2025 Nov 6;16:1698494. doi: 10.3389/fpls.2025.1698494

Split nitrogen applications provide no benefit over a single well timed application in rainfed winter wheat

Another reason to N-Rich Strip.

Yet just one more data set showing the value of in-season nitrogen and why the N-Rich Strip concept works so well.

Questions or comments please feel free to reach out.

Brian Arnall b.arnall@okstate.edu

Acknowledgements:

Oklahoma Wheat Commission and Oklahoma Fertilizer Checkoff for Funding.

Double Crop Options After Wheat (KSU Edition)

Stolen from the KSU e-Update June 5th 2025.

Double cropping after wheat harvest can be a high-risk venture for grain crops. The remaining growing season is relatively short. Hot and/or dry conditions in July and August may cause problems with germination, emergence, seed set, or grain fill. Ample soil moisture this year can aid in establishing a successful crop after wheat harvest. Double-cropping forages after wheat works well even in drier regions of the state.

The most common double crop grain options are soybean, sorghum, and sunflower. Other possibilities include summer annual forages and specialized crops such as proso millet or other short-season summer crops, even corn. Cover crops are also an option for planting after wheat (see the companion eUpdate article “Cover crops grown post-wheat for forage”).

Be aware of herbicide carryover potential

One major planting consideration after wheat is the potential for herbicide carryover. Many herbicides applied to wheat are Group 2 herbicides in the sulfonylurea family with the potential to remain in the soil after harvest. If a herbicide such as chlorsulfuron (Glean, Finesse, others) or metsulfuron (Ally) has been used, then the most tolerant double crop will be sulfonylurea-resistant varieties of soybean (STS, SR, Bolt) or other crops. When choosing to use herbicide-resistant varieties, be sure to match the resistance trait with the specific herbicide (not only the herbicide group) that you used. This is especially true when looking at sunflowers as a double crop. There are sunflowers with the Clearfield trait, which allows Beyond herbicide applications, and ExpressSun sunflowers, which allow an application of Express herbicide. While both of these herbicides are Group 2 (ALS-inhibiting herbicides), the Clearfield trait and ExpressSun are not interchangeable, and plant damage can result from other Group 2 herbicides.

Less information is available regarding the herbicide carryover potential of wheat herbicides to cover crops. There is little or no mention of rotational restrictions for specific cover crops on the labels of most herbicides. However, this does not mean there are no restrictions. Generally, there will be a statement that indicates “no other crops” should be planted for a specified amount of time, or that a bioassay must be conducted prior to planting the crop.

Burndown of summer annual weeds present at planting is essential for successful double-cropping. Assuming glyphosate-resistant kochia and pigweeds are present, combinations of glyphosate with products such as saflufenacil (Sharpen) or tiafenacil (Reviton), or alternative treatments such as paraquat may be required. Dicamba or 2,4-D may also be considered if the soybean varieties with appropriate herbicide resistance traits are planted. In addition, residual herbicides for the double crop should be applied at this time.

Management, production costs, and yield outlooks for double crop options are discussed below.

Soybeans

Soybeans are likely the most commonly used crop for double cropping, especially in central and eastern Kansas (Figure 1). With glyphosate-resistant varieties, often the only production cost for planting double crop soybeans was the seed, an application of glyphosate, and the fuel and equipment costs associated with planting, spraying, and harvesting. However, the spread of herbicide-resistant weeds means additional herbicides will be required to achieve acceptable control and minimize the risk of further development of resistant weeds.

Weed control. The weed control cost cannot really be counted against the soybeans, since that cost should occur whether or not a soybean crop is present. In fact, having soybeans on the field may reduce herbicide costs compared to leaving the field fallow. Still, it is recommended to apply a pre-emergence residual herbicide before or at planting time. Later in the summer, a healthy soybean canopy may suppress weeds enough that a late-summer post-emergence application may not be needed.

Variety selection for double cropping is important. Soybeans flower in response to a combination of temperature and day length, so shifting to an earlier-maturing variety when planting late in a double crop situation will result in very short plants with pods that are close to the ground. Planting a variety with the same or perhaps even slightly later maturity rating (compared to soybeans planted at a typical planting date) will allow the plant to develop a larger canopy before flowering. Planting a variety that is too much later in maturity, however, increases the risk that the beans may not mature before frost, especially if long periods of drought slow growth. The goal is to maximize the length of the growing season of the crop, so prompt planting after wheat harvest time is critical. The earlier you can plant, the higher the yield potential of the crop if moisture is not a limiting factor.

Fertilizer considerations. Adding some nitrogen (N) to double-crop soybeans may be beneficial if the previous wheat yield was high and the soil N was depleted. A soil test before wheat harvest for N levels is recommended. Use no more than 30 lbs/acre of N. It would be ideal to knife-in the fertilizer. If that is not possible, banding it on the soil surface would be acceptable. Do not apply N in the furrow with soybean seed as severe stand loss can occur.

Seeding rates and row spacing. Seeding rate can be slightly increased if soybeans are planted too late in order to increase canopy development. Narrow row spacing (15-inch or less) has often resulted in a yield advantage compared to 30-inch rows in late plantings. Soybeans planted in narrow rows will canopy over more quickly than in wide rows, which is important when the length of the growing season is shortened. Narrow rows also offer the benefits of increasing early-season light capture, suppressing weeds, and reducing erosion. On the other hand, the advantage of planting in wide rows is that the bottom pods will usually be slightly higher off the soil surface to aid harvest. The other consideration is planting equipment. Often, no-till planters will handle wheat residue better and place seeds more precisely than drills, although the difference has narrowed in recent years.

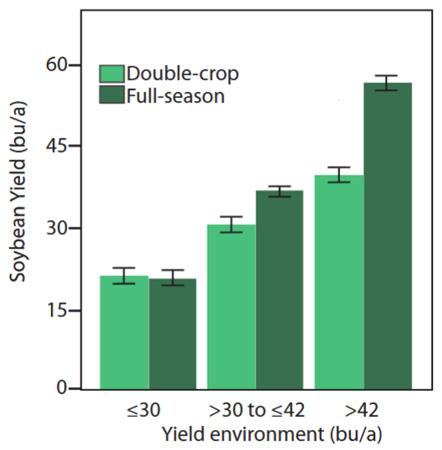

What are typical yield expectations for double-crop soybeans? It varies considerably depending on moisture and temperature, but yields are usually several bushels less than full-season soybeans. A long-term average of 20 bushels per acre is often mentioned when discussing double-crop soybeans in central and northeast Kansas. Rainfall amount and distribution can cause a wide variation in yields from year to year. Double-crop soybean yields typically are much better as you move farther southeast in Kansas, often ranging from 20 to 40 bushels per acre.

A recent publication explores the potential yield of double-crop soybeans relative to full-season yield (Figure 2) and the most limiting factors affecting the yields for double-crop soybeans. The link to this article is: https://bookstore.ksre.ksu.edu/pubs/MF3461.pdf.

Grain Sorghum

Grain sorghum is another double crop option. Unlike soybeans, sorghum hybrids for double cropping should be earlier maturing hybrids. Sorghum development is primarily driven by the accumulation of heat units, and the double crop growing season is too short to allow medium-late or late hybrids to mature before the first frost in most of Kansas.

Seeding rates and row spacing. Late-planted sorghum likely will not tiller as much as early plantings and can benefit from slightly higher seeding rates than would be used for sorghum planted at an earlier date. Narrow row spacing is advised, especially if the outlook for rainfall is good.

Fertilizer considerations. A key component for the estimation of N application rates is the yield potential. This will largely determine the N needs. It is also important to consider potential residual N from the wheat crop. This can be particularly important when wheat yields are lower than expected. In that situation, additional available N may be present in the soil. Assess the amount of profile N by taking soil samples at a depth of 24 inches and submitting them for analysis at a soil testing laboratory.

Double crop sorghum planted into average or greater-than-average amounts of wheat residue can result in a challenging amount of residue to deal with when planting next year’s crop. Nitrogen fertilizer can be tied up by wheat residue, so use application methods to minimize tie-up, such as knifing into the soil below the residue.

Weed control. Weed control can be important in double-crop sorghum. Warm-season annual grasses, such as crabgrass, can reduce double-crop sorghum yields. Using a chloroacetamide-and-atrazine pre-emergence product may be key to successful double-crop sorghum production. Herbicide-resistant grain sorghum varieties will allow the use of imazamox (Imiflex in igrowth sorghums) or quizalofop (FirstAct in DoubleTeam grain sorghum) that can control summer annual grasses.

No-till studies at Hesston documented 4-year average double crop sorghum yields of 75 bushels per acre compared to about 90 bushels per acre for full-season sorghum. A different 10-year study that did not have double crop planting but did compare early- and late-planting dates averaged 73 bushels per acre for May planting vs. 68 bushels per acre for June planting.

Sunflowers

Sunflowers can be a successful double crop option anywhere in the state, provided there is enough moisture at planting time to get a stand. Sunflowers need more moisture than any other crop to germinate and emerge because of the large seed. Therefore, stand establishment is important. Planting immediately after wheat harvest on a limited irrigation field can be a good fit to help with stand establishment.

Seeding rates and hybrid selection. When double-cropping sunflowers, producers should use similar seeding rates to what is typical for the area for full-season sunflowers. While full-season sunflowers can be successful in double-crop production, utilizing shorter-season hybrids can increase the likelihood of the sunflowers blooming and maturing before a killing frost.

Weed control. First, it is important to check the herbicide applications on the wheat. The rotation restriction to sunflowers after several commonly used wheat herbicides is 22-24 months.

Weed control can be an issue with double-crop sunflowers since herbicide options are limited, especially post-emergence. Thus, controlling weeds prior to sunflower planting is critical and may be complicated pre-plant restrictions for some herbicides. Planting Clearfield or ExpressSun sunflowers will provide additional post-emergence herbicide options, but ALS-resistant kochia and pigweeds still won’t be controlled. Imazamox (Beyond in Clearfield sunflower) has activity on small annual grasses as well as many broadleaf weeds, if they are not ALS-resistant.

Summer annual forages

With mid-July plantings, and where herbicide carryover issues are not a concern, summer annual sorghum-type forages are also a good double crop option. A study planted July 21, 2008 near Holton, when summer rainfall was very favorable, provided yields of 2.5 to 3 tons dry matter/acre for hybrid pearl millet and sudangrass at the low end to 4 to 5 tons dry matter/acre for forage sorghum, BMR forage sorghum, photoperiod sensitive forage sorghum, and sorghum x sudangrass hybrids. Earlier plantings may produce even more tonnage, as long as there is adequate August rainfall.

One challenge with late-planted summer annual forages is getting them to dry down when harvest is delayed until mid- to late-September. Wrapping bales or bagging to make silage are good ways to deal with the higher moisture forage this late in the year.

Corn

Is double-crop corn a viable option? Corn is typically not recommended for late June or July plantings because yield is usually substantially less than when planted earlier.

Typically, mid-July planted corn struggles during pollination and seldom receives sufficient heat units to fill grain before frost. Very short-season corn hybrids (80 to 95 RM) have the greatest chance of maturing before frost in double crop plantings, but generally have less yield potential when compared to hybrids of 100 RM or more used for full-season plantings. Short-season hybrids often set the ear fairly close to the ground, increasing the harvest difficulty. Glyphosate-resistant hybrids will make weed control easier with double crop corn, but problems remain present with late-emerging summer weeds such as pigweeds, velvetleaf, and large crabgrass. Keep in mind, corn is very susceptible to carryover of most residual ALS herbicides used in wheat.

Considerations for altering seeding rates and variety/hybrid maturity for the crops discussed above are summarized in Table 1.

Table 1. Seeding rate and variety/hybrid relative maturity considerations for double crops compared to full-season.

| Crop | Seeding rate | Relative maturity |

| ???????? Difference between double crop and full-season ???????? | ||

| Soybean | Increase | No change or longer |

| Sorghum | Increase | Shorter |

| Sunflower | No change | Shorter |

| Corn | No change | Shorter |

Volunteer wheat control

One of the issues with double cropping that is often overlooked by producers is the potential for volunteer wheat in the crop following wheat. If volunteer wheat emerges and goes uncontrolled, it can cause serious problems for nearby wheat fields in the fall as a host for the wheat streak mosaic complex of viruses [wheat streak mosaic (WSMV), High Plains disease (HPD), and triticum mosaic (TriMV)] that are transmitted by the wheat curl mite (WCM).

Volunteer wheat can generally be controlled fairly well with glyphosate or Group 1 herbicides such as quizalofop (Assure II, others), clethodim (Select Max, others), or sethodydim (Poast Plus, others), but control is reduced during times of drought stress. Atrazine can provide control of volunteer wheat in double-crop corn or sorghum, but control can be erratic depending on rainfall patterns.

For more detailed information about herbicides, see the “2025 Chemical Weed Control for Field Crops, Pastures, and Noncropland” guide available online at https://www.bookstore.ksre.ksu.edu/pubs/CHEMWEEDGUIDE.pdf or check with your local K-State Research and Extension office for a paper copy. The use of trade names is for clarity to readers and does not imply endorsement of a particular product, nor does exclusion imply non-approval. Always consult the herbicide label for the most current use requirements.

To Subscribe to the KSU Agronomy E-Updates follow this link

https://eupdate.agronomy.ksu.edu/index_new_prep.php

Authors contributing to the post

Sarah Lancaster, Weed Management Specialist

slancaster@ksu.edu

John Holman, Cropping Systems Agronomist

jholman@ksu.edu

Logan Simon, Southwest Area Agronomist

lsimon@ksu.edu

Tina Sullivan, Northeast Area Agronomist

tsullivan@ksu.edu

Jeanne Falk Jones, Multi-County Agronomist

jfalkjones@ksu.edu

Boosting Wheat Grain Protein: Smart Spray Strategies for Better Grain Quality

Brian Arnall, Precision Nutrient Management Specialist

Samson Abiola, PNM Ph.D. Student.

Wheat Protein and Technology challenge

For wheat growers, achieving both high yields and good protein content is a constant challenge. Wheat contributes about 20% of the world’s calories, making it a vital crop for global nutrition. Every season, we face the question of how to boost grain protein concentration (GPC) without sacrificing the yield.

Traditional approaches often involve applying more nitrogen (N) early in the season. While this can help, it is often wasteful, environmentally problematic, and does not always translate to higher protein levels at harvest. The effectiveness of N applications depends not just on timing but also on the spray technology used, including the N source, nozzle type, and droplet size. While protein premiums are never guaranteed, we wanted to develop recommendations prior to the need.

The Research Approach: Timing and Technology

Our research team conducted a comprehensive three-year study (2019-2022) across three Oklahoma locations (Perkins, Lake Carl Blackwell, and Chickasha) to investigate how different combinations of N sources, nozzle types, and droplet sizes affect protein when applied during flowering. We considered two N sources (urea-ammonium nitrate (UAN) and aqueous urea [Aq. Urea]). We also evaluated three nozzle types: Standard flat fan (FF) nozzles with a traditional 110° spray angle, 3D nozzles with three-dimensional spray patterns that enhance canopy penetration, Twin (TW) nozzles with dual forward and rear facing sprays (30° forward and backward)

Finally, we tested both fine droplets (below 141 microns) and coarse droplets (≥141 microns). All applications were made at flowering i.e., when you start seeing yellow anthers sticking out of the wheat heads. Both UAN and Aq. urea were applied at a 20 gpa application rate with a 1:1 dilution with water delivering approximately 30 lbs. of N per acre.

What We Found: More Protein Without Hurting Yield

The big news? Spraying N at flowering boosted wheat protein by 12% without sacrificing yield. This held true across fields yielding anywhere from 30 to 86 bushels per acre. Why doesn’t it hurt yield? By flowering time, your wheat has already “decided” how many heads and kernels it will produce. The N you spray at this stage goes straight to building protein in those existing kernels.

One important caution: Mother Nature still calls the shots, so keep an eye on the forecast before planning your application. If the weather is hot and dry, this is not a good idea. First, those environments typically result in higher protein anyways. But low humidity will significantly increase the likelihood of burn.

Lake Carl Blackwell Findings: UAN Takes the Lead

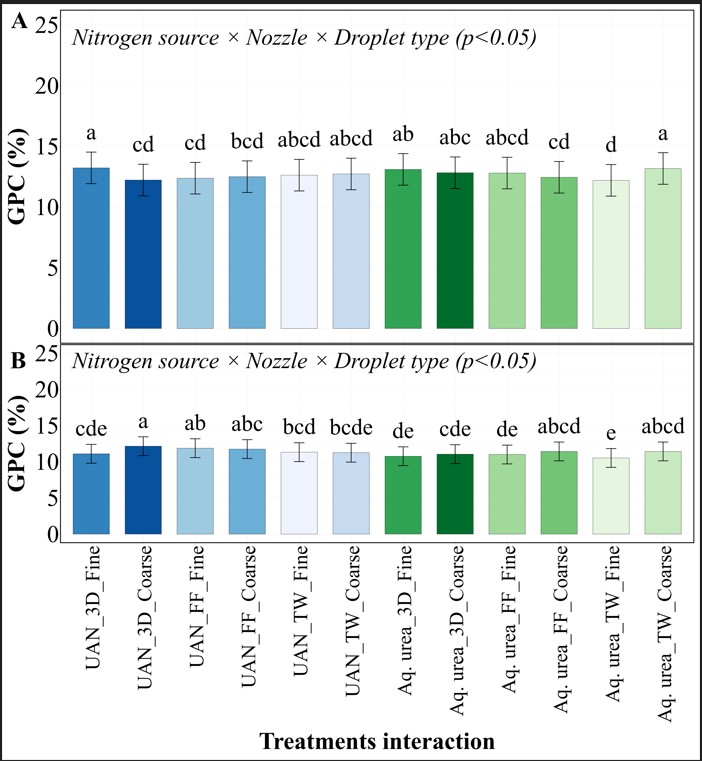

At our Lake Carl Blackwell site, we saw our highest protein levels reaching up to 16.3% in some plots. In 2020-21, UAN clearly beat Aq. urea (14.7% vs. 14.0% protein). Both were much better than not applying any N at flowering (13.1%) (Figure 1A). Also, the 3D nozzle gave us the highest protein (14.7%), outperforming the control but performing similarly to FF (14.0%) and TW nozzles (14.2% (Figure 1B). The next year (2021-22) showed us something interesting, the combination of N source and droplet size really matters. UAN with fine droplets hit 14.6% protein, similar to UAN with coarse droplets (14.4%) and Aq. urea with coarse droplets (14.3%), but Aq. urea with fine droplets fell behind at just 13.8% (Figure 1C).

Chickasha Results: Matching Your N to the Right Droplet Size

At Chickasha, protein ranged from 10.1% to 13.8% across the two years we studied. In 2021-22, UAN beat Aq. urea (12.7% vs. 12.2%), and both beat the control (11.8%) (Figure 2A). Also, the 3D nozzle (12.8%) outperformed both FF and TW nozzles (both 12.2%) (Figure 2B).

In 2020-21, we found that the combination of N source, nozzle type, and droplet size all worked together to affect protein. The winning combination was UAN with 3D nozzle and fine droplets (13.23% protein), which performed similarly to Aq. urea with TW nozzle and coarse droplets (13.18%) (Figure 2C). The least performer was Aq. urea with TW nozzles and fine droplets (12.20%) among the treatments. This shows how weather and growing conditions can change which factors matter most from year to year

Perkins Results: Getting Every Detail Right

At our Perkins site, we saw protein levels ranging from 10% to 13.1%. Here, the combination of all three factors (N source, nozzle type, and droplet size) made a huge difference. The best setup was UAN with 3D nozzle and coarse droplets (12.2% protein). The worst was Aq. urea with TW nozzle and fine droplets (10.5%) (Figure 3). That’s a 15% difference that could mean the difference between premium and feed-grade wheat!

UAN consistently outperformed Aq. Urea across all setups. For example, UAN with 3D nozzle and coarse droplets produced 10% higher protein than the same setup with Aq. Urea.

Equipment and Application Recommendations

Over the three years UAN consistently outperformed perform Aq. urea, showing there is no need for a special formulation and that commercially available UAN is all we really need as a source. While no nozzle type significantly stood out across all sites the 3-D nozzle did show up a couple times as being statistically better. So the important message would be that while the high tech nozzles could provide some value the traditional flat fan performed quite well. While some differences were seen in droplet size, the lack of consistency leads us to say focus on good coverage with limited drift.

Take-Home Messages

- Foliar N at flowering boosted wheat protein by 12% without affecting yield multiple growing seasons and locations. This increase was from 0.5 to nearly 2.0 % protein.

- Nitrogen source matters – UAN consistently outperformed Aq. Urea.

- Your spray technology mattered but not lot – and 3D nozzles generally gave the best results. The good ole flat fans nozzles still did quite will.

- Match droplet size to your setup – generally fine for UAN and coarse for Aq. Urea.

- This targeted approach enhances grain quality without sacrificing yield, potentially improving grain prices and profitability while using N more efficiently.

- Mother Nature still calls the shots, so keep an eye on the forecast before planning your application. If the weather is hot and dry, this is not a good idea. First, those environments typically result in higher protein anyways. But low humidity will significantly increase the likelihood of burn.

This blog was written based upon the data published in the manuscript “Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement” which is available for free reading and downloading at https://www.mdpi.com/2077-0472/15/8/812

Any questions or comments feel free to contact me. b.arnall@okstate.edu

Nitrogen and Sulfur in Wheat

Brian Arnall, Precision Nutrient Management Specialist

Samson Abiola, PNM Ph.D. Student.

Nitrogen timing in wheat production is not a new topic on this blog, in-fact its the majority. But not often do we dive into the application of sulfur. And as it is top-dressing season I thought it would be a great opportunity to look at summary of a project I have been running since the fall of 2017 which the team has call the Protein Progression Study. The objective was to evaluate the impact of N and S application timings on winter wheat grain yield and protein. With a goal of looking at the ratio of the N split along with the addition of S and late season N and S, in such a way that we could determine BMP for maximizing grain yield and protein.

My work in the past has shown two things consistently, that spring N is better on the average and S responses have been limited to deep sandy soils in wet years. Way back when (2013) on farm response strips showed high residual N at depth and no response to S. https://osunpk.com/2013/06/28/response-to-npks-strips-across-oklahoma/. But there has been a lot of grain grown since that time expectations are that we should/are seeing an increase in S response. In fact Kansas State is seeing more S response, especially in the well drained soils in east half of the state.

Some KSU Sulfur works.

https://www.ksre.k-state.edu/news/stories/2022/04/video-sulfur-deficiency-in-wheat.html

https://eupdate.agronomy.ksu.edu/article/sulfur-deficiency-in-wheat-364-1

Click to access sulphur-in-kansas-plant-soil-and-fertilizer-considerations_MF2264.pdf

So the Protein Progression Project was established in 2017 and where ever we had space we would drop in the study. So in the end across six seasons we had 13 trials spread over five locations. Site-years varied by location: Chickasha (2018-2022), Lake Carl Blackwell (2018-2023), Ballagh (2020), Perkins (2021), and Caldwell (2021).

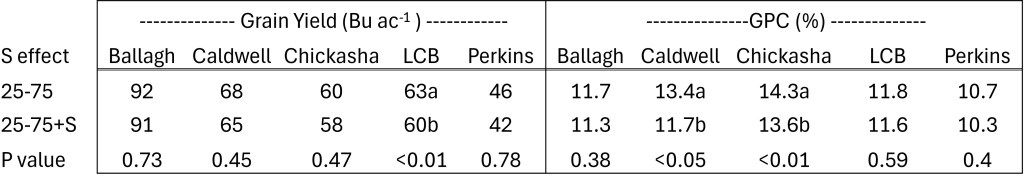

First lets just dive into the the N application were we looked at 100% pre vs 50-50 split and 25-75 split (Table 2.) Based upon the wealth of previous work https://osunpk.com/2022/08/26/impact-of-nitrogen-timing-2021-22-version/, its not much of a surprise that split application out preformed preplant and that having the majority applied in-season tended to better grain yields and protein values.

This next table is were things get to be un-expected. While the data below is presented by location, we did run each site year by itself. In no one site year did S statistically, or numerically increase yield. As you can see in Table 2 below, the only statistical response was a negative yield response to S. And you can not ignore the trend that numerically, adding S had consistently lower yields. Even more surprising was the same trend was seen in Protein.

One aspect of Protein Progression trials were that while 0-6″ soil test S tended to be low. We would often find pretty high levels of S when we sampled deeper, especially when there was a clay increase with depth. Sulfur tends to be held by the clay in our subsoil. We are also looking at better understanding the relationship between N and S. In fact a review article published in 2010 discussed that the N and S ratio can negative influence crop production when either one of the elements becomes un-balanced. For example we are seeing more often in corn that when N is over applied we can experience yield loss, unless we apply S. Meaning at 200 lbs of N we make 275 BPA, at 300 N lbs we make 250, but 300 N plus 20 S we can make 275 again. Part of the rationale is that excessive N limits S mineralization. On the flip side if S is applied while N is deficient and yield decrease could be experienced. Maybe that is what we are seeing in this date. Either way, this data is why the Precision Nutrient Management program is spending a fair amount of efforts in understanding the N x S relationship in wheat (which we are looking at milling quality also) and corn.

A quick dive into increasing protein with late N applications. At three of the five location GPC was significantly increased with Late N. In most cases the anthesis (flowering) application was the highest with exception of Caldwell. We will have another blog coming out in a month that digs into anthesis applied N at a much deeper level, looking at source, nozzle and droplet sizes.

Looking at this study in a vacuum we can say that it probably best to split apply your N and that in central and northern Ok the addition of S in rainfed wheat doesn’t offer great ROI. If I look at the whole picture of all my work and experience I would offer this. For grain only wheat, the majority if not all N should be applied in-season sometime between green up and two weeks after hollow stem. I have had positive yield responses to S applied top-dress, but it has always been deep sandy soils and wet seasons. I have not have much is any response to S in heavier soil, especially if there is a clay increase in the two feet of profile. So my general S recommendation is 10 lbs in sandy soils and if you show low soil test S in heavier ground and you are trying to push grain yields, then you could consider the addition of S as a potential insurance. That said, I haven’t seen much proof of it.

Take Homes

* Split application of nitrogen resulted in higher grain yields and protein concentrations when compared to 100% preplant.

* Putting on 75% of the total N in-season tended to result in higher grain yields and protein concentrations when compared to 50-50 split.

* Adding 10 lbs of S topdress did not result in any increase in grain yield or protein.

A big Thanks to the collaborators providing on-farm locations for this project. Ballagh Family Farms, Turek Family Farms and Tyler Knight.

Citation. Jamal, A.,*, Y. Moon, M. Abdin. 2010 Review article. Sulphur -a general overview and interaction with nitrogen. AJCS 4(7):523-529 (2010). ISSN:1835-2707.

Any questions or comments feel free to contact me. b.arnall@okstate.edu

A comparison of four nitrogen sources in No-till Wheat.

Jolee Derrick, Precision Nutrient Management Masters Student.

Brian Arnall, Precision Nutrient Management Specialist.

Nitrogen (N) fertilizer’s ability to be utilized by a production system is reliant upon the surrounding environment. The state of Oklahoma’s diverse climate presents unique challenges for producers aiming to apply fertilizers effectively and mitigate the adverse effects of unfavorable conditions on nitrogen fertilizers. To lessen the effect that unfavorable environments can have on N fertilizers, chemical additions have been introduced to base fertilizers to give the best possible chance at an impact. With that in mind, a study was conducted to investigate the impact of N sources and application timings on winter wheat grain yield and protein, aiming to identify both the agronomic effects of these sources and how variations in their timing may influence the crop. Included below is a figure of where and when the trials were conducted.

In each of the trials, four N sources (Urea, SuperU, UAN, and UAN + Anvol) were analyzed across a range of timings. The sources were categorized on two criteria: application type, distinguishing between dry and liquid sources, and the presence of additives versus non-additives. The two N sources were Urea and UAN. The other products in this study were SuperU and Anvol. SuperU is a N product that has Dicyandiamide (DCD) and N- (n-butyl) thiophosphoric triamide (NBPT) incorporated into a Urea base. Anvol is an additive product which contains NBPT and Duromide and can be incorporated with dry or liquid N sources.

For additional clarification, N- (n-butyl) thiophosphoric triamide is a urease inhibitor which prevents the conversion of urea to ammonia. Duromide is a molecule which is intended to slow the breakdown of NBPT. DCD is a nitrification inhibitor that slows the conversion of ammonium to nitrate.

Urea is a stable molecule which in the presence of moisture is quickly converted to stable ammonium (NH4), however it can be converted to ammonia gas (NH3) by the enzyme urease beforehand. Additionally, when urea is left on the soil surface and not incorporated via tillage or ½ inch of a precipitation event, the NH4 that was created from urea can be converted back to NH3 and gasses off. So, the use of urease inhibitors is implemented to allow more time for incorporation of the urea into the soil.

Ammonium in the soil is quickly converted to nitrate (NO3) by soil microbes when soil temperature is above 50F°. When N is in the NO3 form it is more susceptible to loss through leaching or denitrification. Therefore, nitrification inhibitors are applied to prevent the conversion of NH4 to NO3.

All treatments were applied at the same rate of 60 lbs of N ac-1, which is well below yield goal rate. A lower N rate was chosen to allow the efficacy of the products to express themselves more clearly, rather than a higher rate that may limit the ability to determine differences between product and rate applied. Furthermore, dry N sources were broadcasted by hand across the plots while liquid sources were applied by backpacking utilizing a handheld boom with streamer nozzles. Application timing dates were analyzed by identifying the growing degree days (GDD) associated with each timing which were correlated with the Feekes physiological growth chart displayed in Figure 3. Over the span of the study, N has been applied over six stages of growth. The range of application dates stems from the fact that it is difficult to get across all the ground exactly when you need to.

Over four years this study was replicated 11 times. Of those 11 site years, three did not show a response to N, so they were removed from further analysis. The graph above shows the average yield of each respective source (across all locations and timings). The data shows there is a statistical difference between SuperU and Urea vs. UAN, but no statistical difference between UAN treated Anvol and any other source. The data indicates that on average, a dry source resulted in a higher yield than when a liquid source was applied. This makes sense considering that in many cases, wheat was planted in heavy residue during cropping seasons that experienced prolonged drought conditions. Therefore, it is thought that a liquid source can get tied up in the residue. This was first reported in a previous blog posting, Its dry and nitrogen cost a lot, what now?, and years later, the same trends in new data indicate the same conclusion.

If we look at all timings and site years averaging together there is no statistical difference between a raw N source and its treated counterpart. This result is not surprising as we would expect that not all environments were conducive to loss pathways that the products prevented. Basically, we would not expect a return on investment in every single site year, and therefore you do not see broad sweeping recommendations. There was a 2-bushel difference between UAN and UAN Anvol. As this was a numerical difference, not a statistical one, I would say that while the yield advantage was not substantial there may be economic environments that would suggest general use.

While the evaluation of the four sources across all timings and locations showed some interesting results, this work was performed to see if there was a timing of application which would have a higher probability of a safened N returning better yields. As you look at the chart above it is good to remember the traditional trend for precipitation in Oklahoma, where we tend to start going dry in November and stay dry through mid-January. Rain fall probability and frequency starts to increase around mid-February, but moisture isn’t consistent until March. This project was performed during some of the dryest winters we have seen in Oklahoma. Also, just a note, since the graph above combines all the sites that have differing application dates the absolute yields are a bit deceiving. For example, the Nov and Feb timings include the locations with our highest yields 80+ bpa per acre, while January and February include our lowest. So, the way this data is represented we should not draw conclusions about best time for N app. For that go read the blogs Impact Nitrogen timing 2021-2022 Version and Is there still time for Nitrogen??

Figure 6a and b. A: The mesonet rainfall totals for Oct -Dec for the Lake Carl Blackwell research station for 2020-2023 A: The mesonet rainfall totals for Jan – April for the Lake Carl Blackwell research station for 2021-2024. The black line on both graphs is the 10 year average.

Now about the source by time. While it’s not always statistical you can see that the dry sources tend to outperform the liquid sources at most timings. Also, while there is never a statistical difference in the raw product and safened, there are trends. SuperU tended to have higher yields than urea when applied in Nov and Dec. It could be hypothesized that the addition of a nitrification inhibitor may have added value, however the UAN + Anvol in November also showed a positive response that would point to the value being derived from urease inhibition. As we move into the period of more consistent rainfall the differences between products start declining, which also makes sense.

The following figures illustrate rainfall events following N application, with the application dates indicated by arrows. Figure 7 corresponds to our trial conducted in 2020-2021, which revealed no statistical differences among the N sources for any timing. However you can see that for the first timing (orange bars) which received 0.7″ of rain two days after application that the yields are uniform than the grey bars with both safened products are numerically greater than the raw product, just makes since as a 0.1″ precipitation event happened 6 days application application and it wasn’t until day 9 that a good incorporating rainfall occurred.

Figure 8 has data the same location one year later, during which we observed statistically significant differences among the dry and liquid N sources. The environmental conditions during 2022 were drier, impacting the incorporation of N applications. The lack incorporating rainfall likely led to tie-up of the UAN on/in the residue, limiting access to plant available N.

It is essential to highlight the environmental conditions encountered throughout this project. From 2020 to 2023, moderate to extreme drought conditions were prevalent. During this period, the influence of a La Niña led to reduced moisture availability. For the first time in an extended period, the 2023-2024 wheat year began under a strong El Niño, which typically results in increased moisture accumulation compared to its La Niña counterpart. Currently, there are indications that a return to a La Niña system may occur by the end of the year, raising the expectation of a potential reversion to drought conditions. Consequently, this research may provide producers with options to consider regarding sources of N application in their production systems.

We plan to update this blog with a deeper analysis of the results seen at each location as soon as possible. But for now, we wanted to share the early look.

At this point the reason for the liquid yield gap is speculation. It could be increased loss via ammonia volatilization or it could be immobilization of the N by microbes. The next step of this process is to understand 1) is the UAN tied up in the residue via immobilization via microbes or is it lost to volatilization. 2) If tied up, what is the time frame between application and immobilization.

Take Home:

- It was observed that during low moisture conditions, dry N sources had significantly better results than liquid counterparts in no-till winter wheat production.

- On average, additive products had no significant impact on grain yield versus base fertilizers, however, when evaluated by location, differences could be found. Responses usually correlated with post-application weather conditions.

- When adequate precipitation was received shortly after application, N sources did not show differences.

Any questions or comments feel free to contact me. b.arnall@okstate.edu

Impact of Nitrogen timing 2021-22 Version

Raedan Sharry, Ph.D. Student Precision Nutrient Management

As wheat planting rapidly approaches for some and gets underway for others, it is without a doubt worth considering the current moisture conditions, the near-term outlook, and how that might influence N management decisions. There is plenty of information located in this blog and many other resources that show the benefits of delayed N management in crops. This is particularly true when considering an extremely long growing season for winter wheat in the southern plains. Given our current soil moisture situation yield expectations given the current soil moisture may be limited until replenishing precipitation occurs. This has many questioning their N management plan.

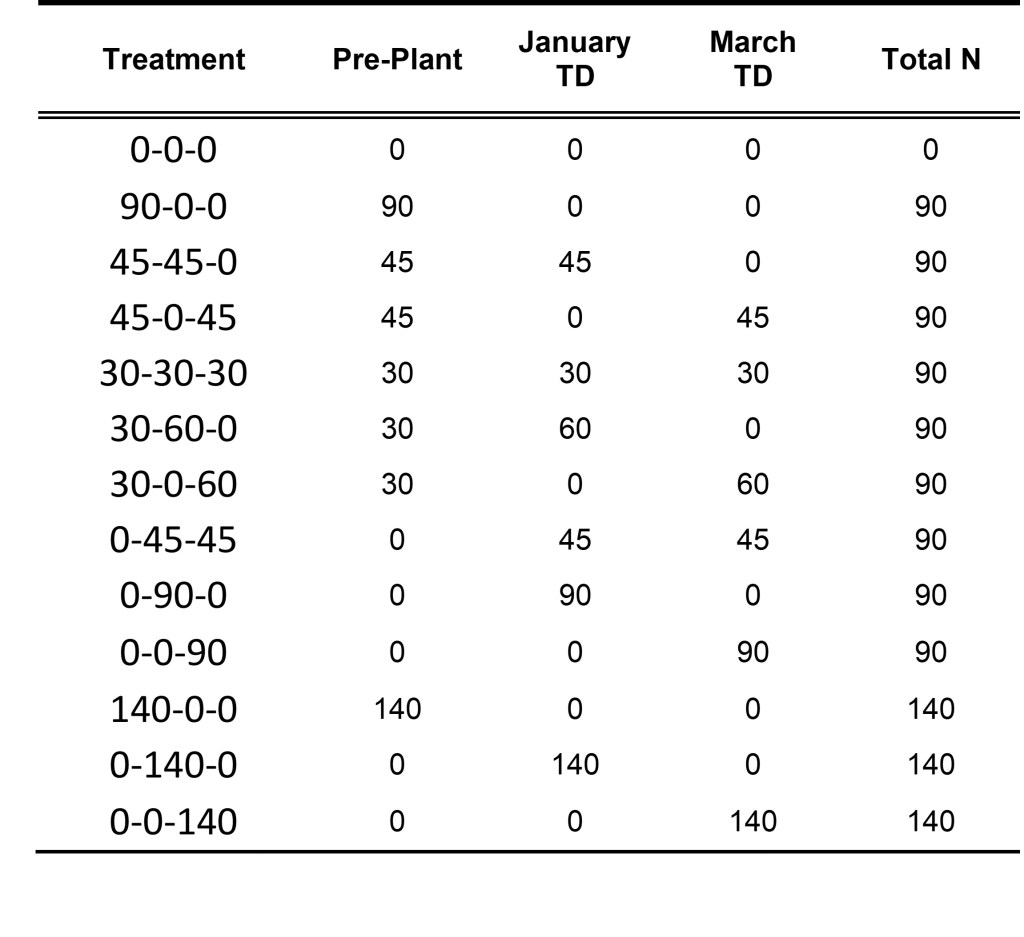

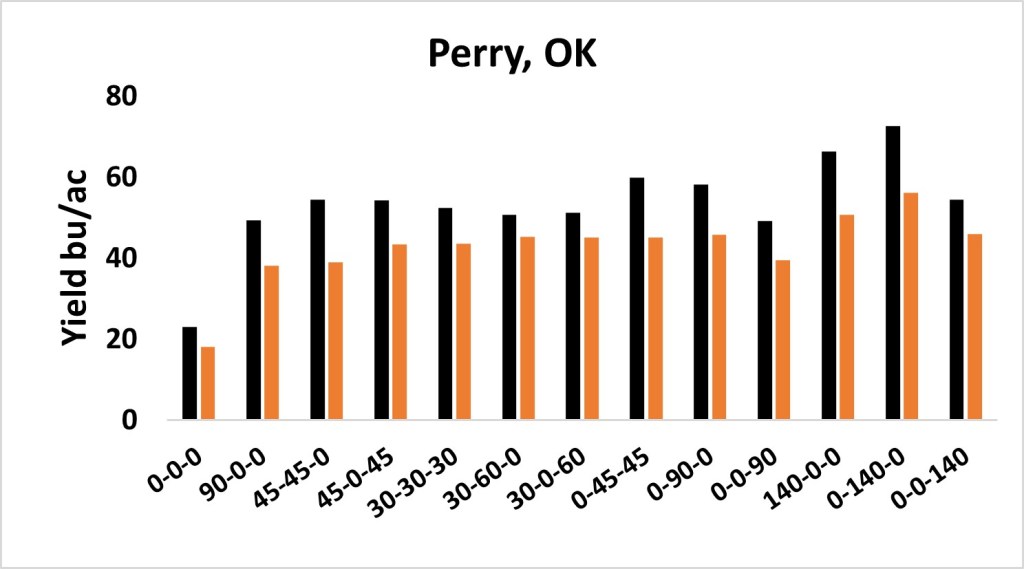

Often when talking about the past N timing results How Late Can You Wait there are comments about the risk of waiting and the crop needing N to get going. Most of the work in the past looked at a single application of N applied at different times and didn’t address split application. But the data from a couple of trials located at Perkins and Perry Oklahoma in the 21-22 season is reinforcing what the past data suggest. These trials consisted of 2 varieties with a 0 N check and 9 combinations of N timings to at 90lbs rate and 3 timings at 140 lbs. of N. Ammonium nitrate (34-0-0) was the N source used in this study to limit the impact of urea volatilization. For both locations we have pre-plant soil test results for the 0-6 and 6-12 inch depths. Both locations at about 30 lbs of total N and OM of 2.0% in the top 6 inches.

The varietal component of this study doesn’t matter in this context so we will leave them unnamed as both cultivars responded very similar to nitrogen timing and rate within each location. The first thing to highlight is both trials were sown in mid-October. October 19th and October 21st to be exact. Both locations received timely rainfall to start the season with approximately 1.5 inches of precipitation falling in half-inch increments between October 25th and November 10th. Top-dress applications in January and March were made on 1/10/22 and 3/24/22 respectively. After the early rainfall events the season was largely dry up until the precipitation in mid-march. So pre-plant fertilizer was incorporated in a fairly timely manner however the January application was applied almost a month before meaningful precipitation occurred. The March application missed the only productive rainfall event until the end of April however this occurred solely due to the application trigger being based on reaching the jointing stage.

If we take what is stated above into consideration it would be hard to imagine that January applied N would provide a boost over pre-plant. The data says different. At both locations pre-plant N cost us bushels compared to treatments containing fertilizer only in January. Even splitting the application did not produce the same result as treatments that only apply N in-season. At the Perry location at the 90 lb. total rate there was no yield difference between any split applications and the 0-90-0 application making the January application more cost effective. While there were no split application treatments made at the 140 lb. rate the 0-140-0 treatment (140 lbs. applied in January) maximized yield. I also think it is important to note that if the March applications would have been applied prior to the rain event immediately preceding them the March application likely would have AT LEAST been competitive with the other treatments given previous research focusing on delayed N applications. Statistically the 90-0-0 and 0-0-90 were in the same grouping for both cultivars.

At the Perkins location the results were not much difference as far as impact of timing. In-fact except for Var 1 at Perkins 0-140-0 was statistically better than all other treatments. Also expect for Var 1 at Perry the 0-90-0 and 140-0-0 were statistically the same. In all cases 90-0-0 yielded less than 0-90-0 but it was not statistical for all comparisons.

The timing component is important as it shows that we are perfectly capable of applying N in-season and being successful. In-fact this work, and other work is starting to show that contrary to past beliefs, split application is not providing any benefit over a single well-timed application. The source of N of this project needs to be consider as the January top-dress application sat on the surface for almost a month before finally receiving just under two-tenths of an inch of precipitation. We will have another blog coming out soon looking at the impact of N sources urea versus UAN when applied in Fall, January, or March very soon.

With these results in mind and current moisture conditions it is only reasonable to consider delayed nitrogen application, not only to increase nitrogen use efficiency and possibly increase yields as well as a virtually guaranteed increase in grain protein, but also as a way to hedge your bet against fertilizer application cost. This work and all the past work support that grain only wheat does not benefit from the application of pre-plant N. By applying N fertilizer now there is a chance that it may become a sunk cost with a poor performing or even failed crop. And if it does start raining, well that pre-plant N will be right there ready to be leached. Being efficient is important in the tight years, and by delaying N application until you are sure the crop requires it may save you a pretty penny or more.

Questions or comments please feel free to reach out.

Brian Arnall b.arnall@okstate.edu

Acknowledgements: EDC Ag Products Co LLC for support of this project.

Oklahoma Wheat Commission and Oklahoma Fertilizer Checkoff for Funding.

In-season N application methods for Sorghum

Raedan Sharry, Ph.D. candidate under advisement of B. Arnall

Brian Arnall, Precision Nutrient Management Specialist

The data about to be reported is from the study we have fondly named “Burn Baby Burn”, you will see why soon enough.

Grain Sorghum production continues to be an important component of many growers crop rotations in the Great Plains. However, for many growers who focus primarily on small grains production, equipment restraints may impose limits on in season nitrogen (N) management. When producers are able to delay the application until in-season it helps to ensure that N is available to the crop at the time of increased uptake during the reproductive stages of the crops life. Producers often have access to equipment and technologies that may be used to take advantage of improved N application timing, but may worry about the negative effects that nitrogen can have if the fertilizer is inadvertently applied to plant material. An experiment was initiated in Central Oklahoma to evaluate the yield response of grain sorghum to in-season nitrogen application methods.

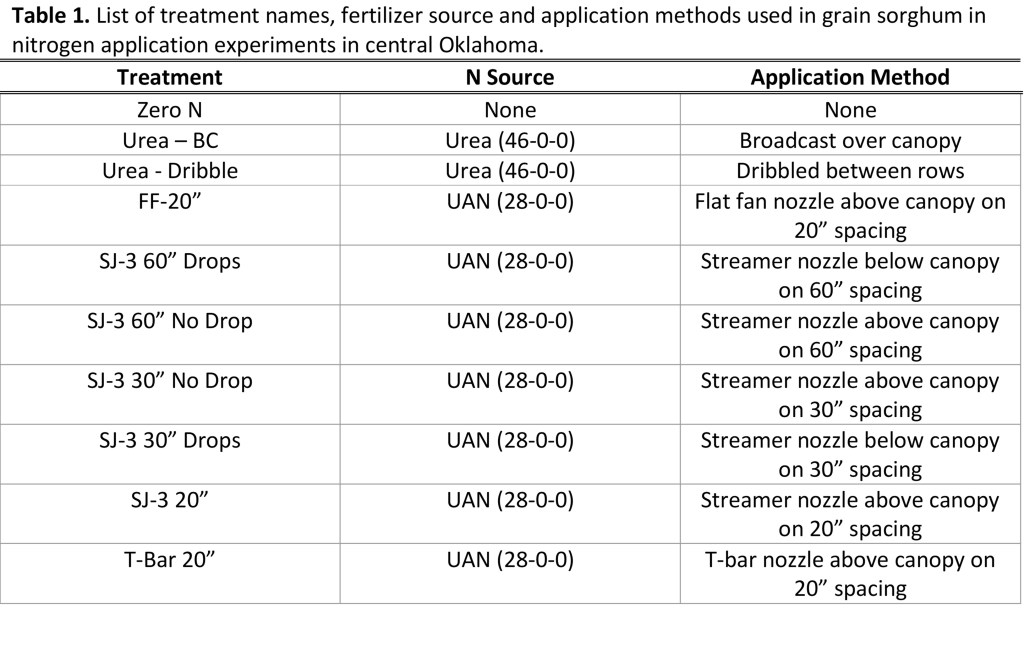

Trials were placed at Lake Carl Blackwell near Stillwater, Perkins and Chickasha Oklahoma and included 9 in-season fertilization methods and a 0 nitrogen control. Treatments are listed in Table 1 below.

In total 120 lbs of N was applied to all treatments receiving in-season applications. 60 lbs was applied at planting to all treatments including the “Zero N Control”. The remaining 60 lbs. of N was applied according to application method in-season. The urea was applied by hand and the liquid treatments a push cart with adjustable boom height (Figure 1) was used to apply the UAN. Applications were made mid day at V8 growth stage. The temperature at the time of all applications was about 90 F and humidity below 75%. Nozzle position for 30″ and 60″ was set for between rows.

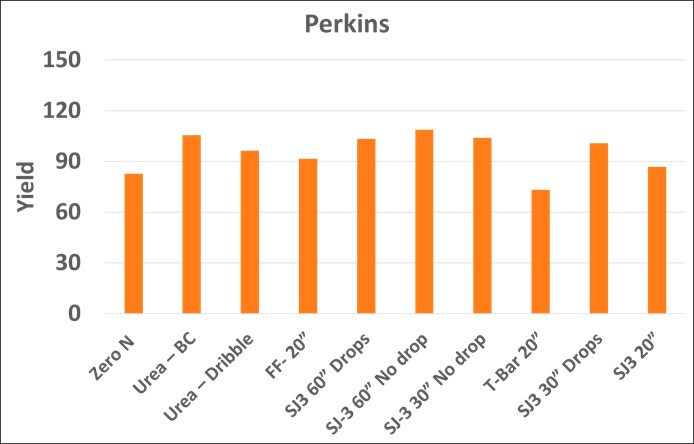

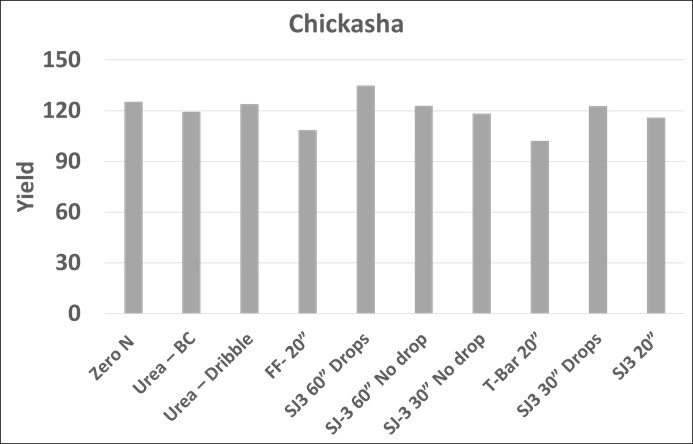

At two of the three locations (Stillwater and Perkins) the addition of 60 lbs. of N in-season increased yield above the control treatment. At the Stillwater (Lake Carl Blackwell) location there were no statistical differences (α=0.05) between in-season fertilized treatments except the T-Bar 20” treatment (Figure 2). The Perkins location (Figure 3) provided a similar result in which again there was no statistical difference between fertilized treatments, excluding the T-Bar 20” treatment.

The Chickasha location differed in that additional in-season nitrogen did not improve yield (Figure 4). While we want a response to applied N, in the case it allows use to solely evaluate the impact of burn associated with N application. The T-bar 20” treatment statistically negatively impacted grain yield and the FlatFan-20″ did at α=0.10, which means we are only 90% confident the yield lose was due to treatment. This response has been consistent across all three locations, on average decreasing yield approximately 21 bu/ac relative to the individual site grain yield average.

Even though it was mentioned for Chickasha, it is also important to note that while it was not statistically significant (α=0.05) the FF- 20” treatment (Flat Fan nozzles above canopy on 20” spacing) trended towards decreasing yields at all 3 locations and is likely detrimental to crop performance. At all locations substantial damage to leaf material was observed, similar to that pictured in Figure 5 below. Several of the treatments damaged leaf material on the plant through burn injury, but most were not negatively impactful on grain yield in the 2021 growing season. Grain sorghum yield did not benefit from moving the application point below the canopy using drop attachments, nor did adjusting nozzle spacing from 30 to 60”. Source was not a significant factor impacting grain yield regardless of it application method.

The observations from this study show that many of the in-season nitrogen application methods that are available to growers will not negatively impact yield. This however does not apply to tools such as the T-Bar. Similar tools that concentrate large amounts of N to leaf material are also likely to produce similar results. It is important to note that the T-bar was used on 20” spacings and not tested otherwise. Moving the spacing of the T-bar may lead to different results.

Growers who are looking to move N applications in their grain sorghum crop to in-season to capture the benefits associated will likely be able to with equipment that is already available to them. While leaf damage may be observed under sub-optimal application methods, damage is unlikely to contribute to significant yield loss. However, growers should keep in mind that environmental conditions may have a significant impact on the results seen from these types of application as growers should always look to limit stress to the plant when possible.

We of course will be putting out a second year of this study and will share the results when we can.

For more information or questions contact

Brian Arnall b.arnall@okstate.edu 405.744.1722

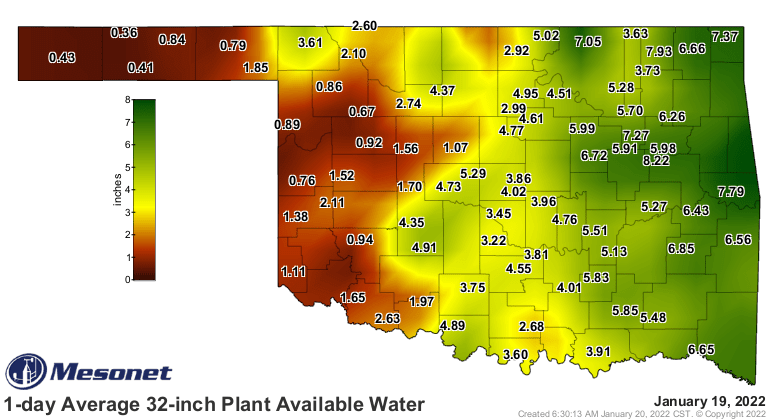

Its dry and nitrogen cost a lot, what now?

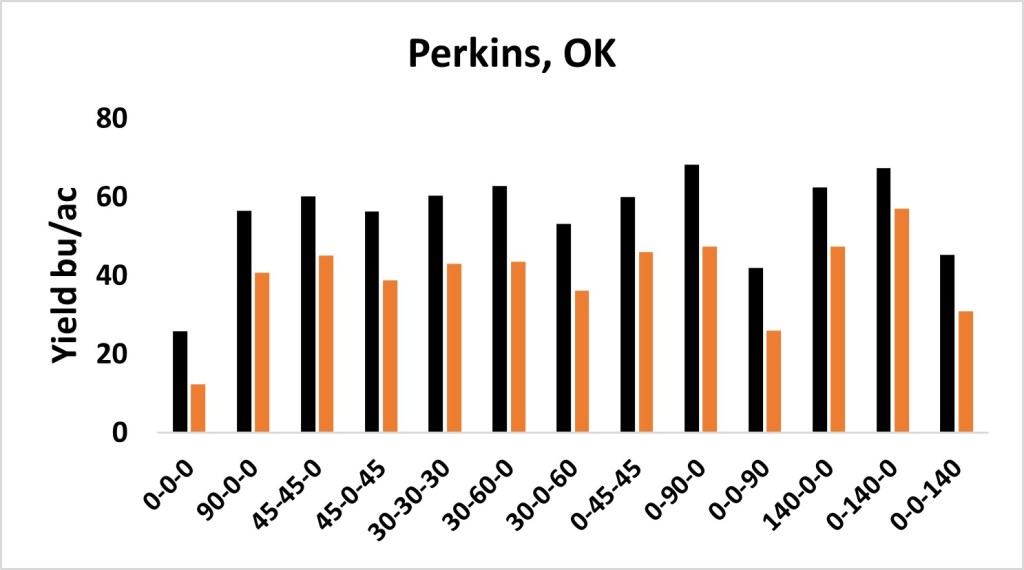

The title says a lot about the primary question I am receiving right now. And the latest long range “forecast” does not make me feel any better about the current situation. But it is what it is and many great plains wheat farmers are having to make a decision.

The current situation in the wheat belt is that we are dry to depth, when the 32 inch PAW is on short supply and this comes from a combination of no rain and above average temperatures.

Fertilizer prices are holding fairly strong, at expensive, and the wheat crop currently seems to be going in reverse. So what is a wheat farmer to do? If we are looking on the bright side the lack of moisture in the surface will help reducing any potential losses through urea volatilization. It does not make the potential for loss zero though. If I am bound and determined to fertilize now, I would be very selective of the source and method of application. The biggest driver, tillage and residue amounts.

- Conventional Till / No residue (plenty of bare soil showing) and small wheat-

- UAN via Streamer nozzles

- Why: With UAN (urea ammonium nitrate) you have a liquid N source that will get onto and into the soil and readily available nitrate. Streaming on will help concentrate the fertilizer and potential reduce any urea volatilization if any dews were to occur. Urea would sit until dissolved and lead to potential losses if the first moisture was heavy dew and not a incorporating rainfall.

- UAN via Streamer nozzles

- No-till / high residue (no bare soil showing)-

- Dry Urea

- Why: If Our residue is dry when the urea is spread the wind will help push it below the residue surface providing protection until a good rain. If UAN is applied to this dry or even slightly damp residue and not washed off with a rainfall in a week or so the amount of N tied up in that residue will likely be significant.

- Dry Urea

- The big wheat (very little bare soil, lots of wheat tissue.

- Urea or UAN Streamer

- Why not Flat fan. At least with the current status the wheat is not growing and bigger wheat has increasing levels of tip die back. So while UAN sprayed on actively growing wheat can be absorbed foliarly, stressed wheat can not do it as well. Plus the UAN that hits dead or damaged tissue will not make it into the plant. The UAN applied via flat fan will need incorporation via rain in a couple days.

- Urea or UAN Streamer

You may have caught in the paragraph above I said, “If I was bound and determined”. If I had the option I am not pulling the trigger until after I have received some good moisture. I fully expect and have already seen rigs running before every decent chance of rain. Unfortunately many of those chances have not panned out and that will remain my concern moving forward. I want to make sure we have some water in the tank before investing in the system.

But now we increase the risk/fear by waiting and the question I get is what if we don’t get good rains or don’t get good incorporating rains. The short answer is, if we don’t get rains the N application is the least of our concerns. If we approach March 15th and we have not had the rains needed to put a little water in the tank and incorporate the N then we are not likely looking at a bumper crop which will need N. What survives in that scenario will be living off deep soil water, and where there is deep soil water there is a good chance of deep N. The shallow soils will be so stressed that nutrient demand will be very little.

Now lets talk waiting and applying N. How late before we just say we are done. To answer I am going to draw from a data set I talk about a lot, the delayed N work by Dr. Souza. This study was started in the fall of 2016 and concluded with the 2020 wheat harvest. In all, twelve trials were established and achieved maturity. This study was designed to evaluate the recovery of winter wheat grain yield and protein after the crop was N stressed. Treatments included an untreated check, pre-plant application and ten in-season treatments. The application of in-season treatments was initiated when N deficiency was confirmed and treatments were applied in progressive order every seven growing days to the point of 63 growing days after visual deficiency (DAVD). A growing degree days is any day that the average daily temperature is at or above 40⁰ F. Ammonium nitrate (NH4NO3) was applied at a rate of 90 lbs N ac-1 for all treatments.

With this data we can answer two questions, first at what point did we lose yield compared to pre-plant and second how late could we apply and still increase yield above the check. So comparing to the pre lets us know how long could we wait with losing yield. Across the trials we lost yield three times by waiting too long, at LCB2017b that was 4/19, Lahoma18 it was around 3/30, and then Newkirk2020 we lost yield by waiting until 4/6. This data is why I am pretty comfortable waiting until mid March when and if needed. Now if we look at the check, that will tell us if things start improving late can we get still get a yield bump with added N. Newkirk 2020 was the only time and place we could increase yield above the zero after the 4/14 additions.

Take Home Message

My recommendation is that if you are not required to take delivery or needing to cover a lot of acres, i.e. time limited, I would not get in a hurry to apply N on this wheat crop. I think if we combine weather by market this a good time to wait and see. Once we get a rain and have some soil moisture it will be time to run the rigs. The crop currently does not need a lot of N so why spend the $. If things don’t improve by mid to late march, consider the wheat a cover and look towards a summer crop with the hopes of rains in April. If you need to take the crop to yield, then you can wait a while longer and still get a return on the N, with hopes the price could come down a bit.

Finally, While I don’t suggest running fertilizer in front of the first chance of rain, I would make sure I had an N-Rich strip on each and every single field. Strips can go out well past green up and serve a great purpose. The N-Rich strip will help you determine if the crop is able to mine any soil N or if the N tank is dry.

Feel free to reach out with questions or comments.

Brian Arnall Precision Nutrient Management Specialist.

b.arnall@okstate.edu

Special thanks to EDC Ag Products Co LLC for suppling NH4NO3 used in the delayed N project.

Relevant past blogs for your reading enjoyment.

The Easy Button for Nitrogen…….

Brian Arnall, Precision Nutrient Management Extension Specialist.

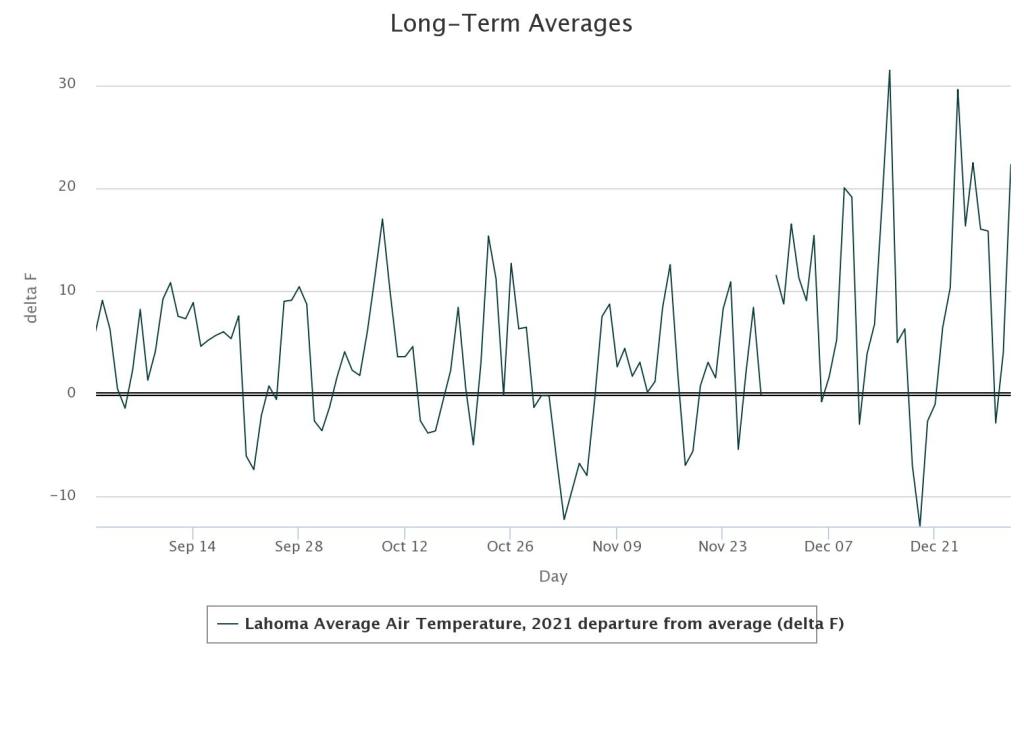

The basics for nitrogen (N) fertilizer rate determination can be described in a mechanistic approach by the Stanford Equation NFert = ( NCrop – NSoil ) / Neff. This equations states that the N fertilizer rate is equal to the amount of nitrogen taken up by the crop minus the amount of nitrogen supply by the soil, divided by the efficiency of the nitrogen fertilizer used. I outline the importance of this equation in the blog “Components of a variable rate nitrogen recommendations“.

There are nitrogen “Easy Buttons” which utilizes averages collected over diverse environments to create accurate N rate recommendations. The best example of this is the yield goal rules of thumb such as wheats 2.0 lbs N per yield goal bushel minus soil test nitrate. Yield goals are generally calculated as the average of the best 3 out of 5 years, or the 5-year average times 20%. Also, the 2.0 lbs of N is more than what is in a bushel as it also adds in an efficiency factor or a 0.5 lbs per bushel cushion. This method and others like it provide an accurate N rate with slight probability of yield loss. However, the rec is often highly imprecise. Meaning that if I apply the method to 100 fields the average will be spot on, however if I look at the performance of the recommendation on a single field, I will likely be disappointed.

When it comes to nitrogen recommendations the Easy button method will use components which help ensure that the rate prescribed will maximize yield 90-95% of the time. For example, take the data presented in Figure 2. Over fifteen years of the long-term winter wheat fertility study near Lahoma, Oklahoma the average pounds of N per bushel to reach economic optimum nitrogen rate (EONR) was 1.6, however if 2.0 of N was applied per bushel yield would have been maximized 13 out of the 15 years. While 2.0 lbs. of N per bushel would have been quite accurate for maximizing yield, it would be highly imprecise as over the 15 years optimum pounds of N per bushel ranged from 0.0 to 3.2.

The trick to improving your N rate recommendation closer to a precise and accurate system is to obtain representative site-specific values for the Stanford Equation NFert = (NCrop – NSoil) / Neff.

Looking at the 15-year long-term data above the yields range from a low of 27 to a high of 88 bushels. Of those 15 years, I personally planted multiple years, usually sometime in October, and many of those years while sowing I could have guessed a range of 55-60 bushel, which just happened to be just above the 15-year average. It was not until February and March when the yield potential really started to express itself. Why, well there is a lot of weather between Oct to March, a lot of environmental positive and negative impacts on that final grain yield. This is the best timing to go out with approaches, models, or techniques to estimate yield potential for N rate recs.

While I am a big fan of soil testing, pre-plant soil samples for N are just a snap shot in time. But the While I am a big fan of soil testing, pre-plant soil samples for N are just a snapshot in time, but the nitrogen cycle Figure 3, will roar on after the soil sample is collected. Organic matter (OM) is the central component of this cycle and drives availability of NH4 and NO3 in the system. For each 1% OM in the top 6″ of the soil there is approximately 1000 lbs of organically bound N. The amount of N going into and out of OM pool is driven by C:N ratio of residues, soil temperature and soil moisture. While we very well what the mechanisms of the cycle are and can model the reactions quite well. Our inability to predict long term weather patterns is the greatest factor limiting our ability to predict future availability of NSoil.

This is where the reader should be asking “how can we get better site specific data” and I begin the discussion on why I have been promoting the of the Sensor Based Nitrogen Rate Calculator (SBNRC) and N-Rich strip method.

Lets talk about how the approach follows Stanford’s mechanistic approach to N management. First the Yield Potential component of the SBNRC which is related to NCrop. In effect researchers have built models over the past two decades that can correlate the NDVI collected from a sensor, such as the GreenSeeker, with the crops biomass and chlorophyll content. If given the number of days the crop has been growing it is possible to use the NDVI collected from the crop as a tool to predict final grain yield. The closer the wheat gets to hollow stem, or the corn gets to tassel, the better the prediction. One reason is that we have allowed more “environmental influence” to happen. Dr. Bill Raun, a founder of the SBNRC concept kept great discussion and data sets on his NUE.OKSTATE.edu website. On the “NUE Website on YP” he provides information on how yield prediction work while on the “NUE Website YP Library” he has not listed every algorithm created, and the math behind them, but also a recipe book for how anyone can create their own algorithm. While there are a lot post sensing stresses that can bring down final grain yield, the models that have been built and continually improved, do quite a good job on predicting final grain yield in-season. Resulting a much more site specific value for NCrop. The blog”Sensing the N-Rich Strip and Using the SBNRC” goes into a further discussion of using the online SBNRC.

That now leaves NSoil, which I will argue is at least as important as NCrop. As weather so greatly influences the nitrogen cycle it would be nice to have a weather station on every field paired with a 0-4 ft soil description which could be incorporated into a model. Given those might be out of reach we have found the the use of a reference strip, high N or low N, really provides an site specific estimate the of nitrogen the crop has access to. If the high N reference (N-Rich) strip is showing up that means the remainder of the field is N deficient. This may be due to losses or lack of mineralization, either way more N is needed. If the N-Rich strip is not evident then the crop is finding enough N outside of the reference strip to support its current growth. This could be that residual N or mineralization is high, or it could mean that crop growth and therefore N demand is low. Having the N check strip in each field allows for a season long evaluation. We can use NDVI to characterize how big or little of a response we have to N. We call this the Response Index (RI). An RI of 1.8 means that we could increase yield by 80% if we add adequate N, if the RI is 1.05 then we are looking at a potential increase of 5%. I have a previous blog which goes into the application of the reference strip. “Nitrogen Rich Strips, a Reminder“

Finally we combine the two, YP and RI. By predicting the yield of the area out side the N-Rich strip we can determine environmental yield potential, YP0. Basically what can the field yield if nothing is added. We multiple YP0 by the RI to get the yield potential with added N, YPN. Then its as simple as N rate = (YPN – YP0 ) x N needed per bushel. So for example if YP0 is 40 bushel RI =2, then YPN is 80 bushel. I need to fertilize the additional 40 bushels of wheat and I can use the 2.0 N per bushel can come up with a top-dress rate of 80 lbs N per acre. We are now incorporating site specific in-season NCrop and NSoil data.

And just a reminder for those of you new to my blog, I have a lot of research documenting that it is not only OK, but often best if we wait on N application in wheat and other crops. Value of In-Season N blog.

Every step we take towards the easy button is often a step towards site specific imprecision due to the use of generalized terms or models. Depending on your goals this very well could be acceptable for your operation, but with nitrogen prices as volatile as they are, should we not be considering pushing the easy button to the side, for now. Let’s add a bit of site-specific data so that we can take advantage of the N the system may be giving us, or the yield we did not expect. Let the N-Rich Strip be that first step.

Relevant Peer Review Publications.

If you have any questions please feel free to contact me @ b.arnall@okstate.edu

Nitrogen Rich Strips, a Reminder

With the recent increase in fertilizer prices just prior to winter wheat planting season I felt it was a good opportunity to bring this older post back up and give it an update. Since the blog was originally written in 2013 there has been a lot of work done both to better understand the nitrogen fertilizer need / timing of winter wheat and efforts to updated and improve the algorithms behind the Sensor Based Nitrogen Rate Calculator.

The Nitrogen Rich Strip, or N-Rich Strip, is a technique/tool/process that I spend a great deal of time working with and talking about. It is one of the most simplistic forms of precision agriculture a producer can adopt. The concept of the N-Rich strip is to have an area in the field that has more nitrogen (N) than the rest. In recent years we have been utilizing Zero-N strips in corn. The approach to some may be new but at one point most producers have had N-Rich Strips in their fields, albeit accidentally. Before the days of auto-steer it was not uncommon, and honestly still is not, to see a area in the field that the fertilizer applicator either doubled up on or skipped. In our pastures and dual purpose/graze out wheat every spring we can see the tell-tale signs of livestock deposits. When over laps or “Cow Pox” become visible we can assume the rest of the field is behind in nitrogen. The goal of an N-Rich Strip is to let the field tell you when it needs more N. Research has shown wheat can be yellow and recover completely and it may even be a benefit. See the link for the Value of In-season Nitrogen at the end of this blog.

What I like most about the N-Rich Strip approach is its Simplicity. The N-Rich Strip is applied and; Scenario 1. The N-Rich Strip becomes visible (Greener) you APPLY NITROGEN, Scenario 2. The strip is not visible you Option A. DON’T APPLY NITROGEN Option B. Apply Nitrogen Anyways. The conclusion to apply N or not is based on the reasoning that the only difference between the N-Rich Strip and the area 10 ft from it is nitrogen, so if the strip is greener the rest of the field needs nitrogen. If there is no difference N is not limiting and our research shows N does not have to be applied. However producers who decide to be risk adverse (in terms of yield) can apply N but it would be advised to do so at a reduce the rate. Now is a good time to note that the N-Rich Strip alone provides a Yes or No, not rate recommendation. At OSU we use the GreenSeeker optical sensor and Sensor Based Nitrogen Rate Calculator (SBNRC) to determine the rate, but that discussion will come later. I equate the change from using yield goal N rate recs to the N-Rich Strip as to going from foam markers to light bars on a sprayer. Not 100% accurate but a great improvement.

Now that we have covered the WHY, lets get down to the nuts and bolts HOW, WHEN, WHERE.

How the strip is applied has more to do with convenience and availability than anything else but there are a few criteria I suggest be met. The strip should be at least 10 ft wide and 300 ft long. The rate should be 40 to 50 lbs N (above the rest of the field) for grain only wheat and canola, 80 lbs N for dual purpose wheat. The normal recommendation is that when applying pre-plant either have a second, higher rate programmed into the applicator or make a second pass over an area already fertilized. Many will choose to rent a pull type spreader with urea for a day, hitting each field.

Also popular are applicators made or adapted for this specific use. ATV sprayers are the most common as they can be multi-purpose. In most cases a 20-25 gallon tank with a 1 gpm pump is placed on the ATV with an 8-10ft breakover boom. The third applicator is a ride away sprayer with a boom running along the rear of the trailer. In all cases when liquid is the source I recommend some form of streamer nozzle.

If this all sounds like to much then the easiest application method might just be a push spreader. No need for trailer or even a truck. In most cases I recommend whichever N source is the easiest, cheapest, and most convenient to apply.

When the strip is applied in winter crops proper timing is regionally dependent. For the Central Great Plains, ideally the fertilizer should be applied pre-plant or soon after. However, in most cases as long as the fertilizer is down by December or even January everything works. Timing is more about how much the wheat is growing. If it is slow growing fall, timing can be delayed. When the N-Rich Strip approach is used on the Eastern Shore in Virginia and Maryland the strips have to be applied at green up. We have been trying this in Oklahoma and Kansas with good success. It is always important to make the tools fit your specific regional needs and practices and not the other way around.