Home » Nitrogen (Page 5)

Category Archives: Nitrogen

Time to start topdressing wheat

My favorite part of the blog “Don’t have an N-Rich Strip? It’d be a lot cooler if you did.”

There are few crop inputs that deliver as much return on investment as nitrogen fertilizer. It takes approximately two pounds of nitrogen, costing approximately $1.00, to produce one bushel of grain worth about $5.00. Of course, nitrogen is not the only yield determining factor in a wheat crop. Also, the law of diminishing marginal returns eventually kicks in, but nitrogen fertilizer is still one of the safest bets in the house.

Top dress nitrogen fertilizer is especially important because it is applied and utilized at a time when the plant is transitioning from vegetative to reproductive growth. Several things, including the number of potential grain sites, are determined just prior to jointing and it is imperative that the plant has the fuel it needs to complete these tasks. Jointing also marks the beginning of rapid nitrogen uptake by the plant which is used to build new leaves, stem, and the…

View original post 707 more words

How to make $100,000 in a day

This is a familiar soap box. SOIL SAMPLE, SOIL SAMPLE, SOIL SAMPLE.

No, this blog post is not about a get rich quick scheme, but there is a way for the average wheat farmer in the southern Great Plains to add $50,000 to $100,000 to the bottom line in a single day. Most soil tests I have pulled this summer have shown 50 to 90 lb/ac of NO3-N in the top 18 inches of soil. Ninety pounds of N equates to about $45 of N fertilizer, and this knowledge could save a 2,500 acre wheat farmer in excess of $100,000 in fertilizer cost. Soil testing is laborious, but the potential economic returns for spending a day or two soil sampling are outstanding.

There is still time to soil sample. Soil samples only take a few days to process once they are in the OSU lab. It is not unusual for transit time to the lab to the slowest part of the process…

View original post 219 more words

Nutrient Products: Stabilizers, Enhancers, Safeners, Biologicals and so on.

In this blog I am not going to tell you what to use or what not to use. In fact I will not mention a single product name. What I will do is hopefully provide some food for thought, new knowledge and direction.

First I want to approach a topic I have been called out on several times. I believe there is a stigma that University researchers and extension specialists do not want products to work. It may seem that way at times but it is far from the truth. The reality is that all of us are scientists and know someone may be inventing the product that changes nutrient management as we speak. The issue is that most of us have been jaded. While I may be younger I have over 11 years experience, testing “products” in the field, and that includes dozens of products. I have sprayed, spread, tossed, drilled, mixed and applied everything under the sun, with hopes that I will see that one thing I am always looking for, MORE GRAIN…

The truth is Everything works Sometimes yet Nothing works ALL the time. I and others in my profession do not expect anything to work 100% of the time, I am personally looking for something that will provide a checkmark in the win column 50% of the time. A win is the result of one of two things, more money in the producers pocket or less nutrients in the water or air. Products can increase vigor, nutrient uptake, chlorophyll concentration, greenness but not yield. What Co-op or elevator pays for any of those attributes? Grain makes green.

So many safeners, stabilizers, enhancers, biologicals, and on and on are available, so what should a producer do? Here are few things to think about. Ask yourself “ what part of my nutrient management plan can I get the most bang from improving”?

If the answer is Nitrogen (N) there are three basic categories: Urease inhibition, Nitrification inhibitor, and slow release. All are methods of preventing loss; the last two are preventing loss from water movement.

Urease inhibitors prevent the conversion of Urea to NH3 (ammonia). This conversion is typically a good thing, unless it happens out in the open. Ideally any urea containing product is incorporated with tillage or rain. However, in No-till when urea is broadcast and no significant rainfall events (>0.5”) occur, N loss is likely. The urea prill starts dissolving in the presence of moisture, this can be a light rain or dew, and urease starts converting urea into NH3. As the system dries and the day warms, if there was not enough moisture to move the NH3 into the soil the wind will drive NH3 into the atmosphere. Nitrogen loss via this pathway can range from 5% to 40% of the total N applied.

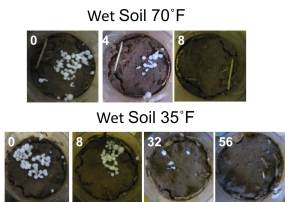

Urea placed on a wet soil under two different temperatures. Number in white is hours after application.

Urea placed on a dry soil, on top no water added, bottom left is moisture from the subsurface, and bottom right is simulated rain fall of 1/2″. Number in white is hours after application.

Nitrification inhibitors prevent the conversion of NH4 into NO3. Both are plant available N sources but NH4 is a positively charged compound that will form a bound with the negatively charged soil particles. Nitrate (NO3) is negatively charged and will flow with the water, in corn country that tends to be right down the tile drainage. Nitrate will also be converted to gasses under wet water logged soil conditions. Nitrate is lost in the presence of water, this means I do not typically recommend nitrification inhibitors for western OK, KS, TX dryland wheat producers.

Slow release N (SRN) comes in a range of forms: coated, long chain polymer, organic and many versions in each category. Again, water is the reason for the use of SRN sources. Slow release N whether coated or other have specific release patterns which are controlled by moisture, temperature and sometimes microbes. The release patterns of SRNS are not the same and may not work across crops and landscapes. For instance in Oklahoma the uptake pattern of nutrients for dryland corn in the North East is not that same as irrigated corn in the West. The little nuances in the growth pattern of a crop can make or break your SRN.

While N products have been on the market for decade’s phosphorus enhancers and stabilizers are relatively new, resulting in many of my peers holding back on providing recommendations until field trials could be conducted. At this point many of us do have a better understanding of what’s available and are able to provide our regional recommendations. Phosphorus products are not sold to prevent loss like their N counterparts; they are sold to make the applied P more available. On a scale of 1 to 10, P reactivity with other elements in the soil is a 9.9. If there is available Ca, Mg, Fe, or Al, phosphorus is reacting with it. In the southern Great Plains it is not uncommon for a soil to have 3,000-5,000 lbs of available Ca, a soil with a pH of 4, yes we have many of those, will have approximately 64,000 lbs of Al in the soil solution. That’s a lot of competition for your fertilizer P and for any substance that is trying to protect it.

I have been testing “biologicals” of all shapes and forms since 2003. While I have not hit any homeruns I have learned quite a bit. Many of these products originate from up north where the weather is kind and organic matter (OM) is high. Where I work the average OM is 0.75% and soil temp is brutal and unforgiving. Our soil does not have many reserves to release nor is it hospitable to foreign bodies.

Soil temperature for Stillwater OK under sod and bare soil conditions. Graph from http://www.Mesonet.org.

I hope you are still hanging on as this next topic is a bit of a soap box for me. Rate, Rate, Rate this aspect is missed both by producers and academia and it drives me crazy. If your crop is sufficient in any growth factor adding more will not increase yield. It goes back to Von Liebig’s LAW of the Minimum. I see too many research studies in which products are tested at optimum fertilization levels. This is just not a fair comparison. On the other hand, time and again I see producers sold on a product because they applied 30% less N or P and cut the same yield. If you let me hand pick 100 farms in Oklahoma I could reduce the N rate by 30% of the average and not lose a bushel on 75 of the farms. Why? Because the rate being used was above optimum in the first place, there is no magic just good agronomy. The list of products that increase the availability of nutrients is a mile long. Increasing nutrient availability is all well and good if you have a deficiency of one of those nutrients. If you don’t, well you have increased the availability of something you did not need in the first place.

University researchers and extension professionals seem to live and die by the statistics, and are told so regularly. We do rely upon the significant differences, LSD’s, and etc to help us understand the likely hood of a treatment causing an effect. However if I see a trend develop, or not develop, over time and landscape regardless of stats I will have no problem making recommendations. The stats help me when I do not have enough information (replications).

Too wrap up, have a goal. Do not just buy a product because of advertised promises or because a friend sells it. There is a right time and place for most of the things out there, but you need to know what that is and if it suits your needs. I also recommend turning to your local Extension office. We do our best to provide unbiased information in hopes of making your operation as sustainable as possible. If you are looking at making sizable investments do some reading, more than just Google. Testimonies are great but should but should not be enough to cut a check. Google Scholar www.google.com/scholar is a good resource for scientific pubs. I have done my best to put together a list of peer reviewed publications and their outcomes. To make the review work I had to be very general about outcome of the research. Either the product increased yield or decreased environmental losses or it had no impact. This was not easy as many of the papers summarize multiple studies. I did my best to make an unbiased recommendation but some could be argued. http://npk.okstate.edu/Trials/products/Product_Peer_Review.8-21-2014.pdf

First hollow stem advisor available on Mesonet

This is a great tool. It looks like we have very little time between green-up and hollowstem.

The advisor uses a mathematical model that predicts the probability of first hollow stem based on soil heat units and wheat first hollow stem category (early, middle, or late). The model was developed by J.D. Carlson at OSU using first hollow stem data from the wheat variety testing program, and model development was made possible through a grant from the Oklahoma Wheat Commission.

You can navigate to…

View original post 322 more words

Nitrogen Rich Strips

The Nitrogen Rich Strip, or N-Rich Strip, is a technique/tool/process that I spend a great deal of time working with and talking about. It is one of the most simplistic forms of precision agriculture a producer can adopt. The concept of the N-Rich strip is to have an area in the field that has more nitrogen (N) than the rest. Due to our fertilizer applicators this is typically a strip. The approach maybe somewhat new but at one point most producers have had N-Rich Strips in their fields, albeit accidentally. Before the days of auto-steer it was not uncommon, and honestly still is not, to see a area in the field that the fertilizer applicator either doubled up on or skipped. In our pastures and dual purpose/graze out wheat every spring we can see the tell-tale signs of livestock deposits. When over laps or “Cow Pox” become visible we can assume the rest of the field is behind in nitrogen. I like to tell producers that the goal of the N-Rich strip is to make a really big cow pie.

- Cow Pox, Image courtesy Kaitlyn Nelson

What I like most about the N-Rich Strip approach is its Simplicity. The N-Rich Strip is applied and; Scenario 1. The N-Rich Strip becomes visible (Greener) you APPLY NITROGEN, Scenario 2. The strip is not visible you Option A. DON’T APPLY NITROGEN Option B. Apply Nitrogen Anyways. The conclusion to apply N or not is based on the reasoning that the only difference between the N-Rich Strip and the area 10 ft from it is nitrogen, so if the strip is greener the rest of the field needs nitrogen. If there is no difference N is not limiting and our research shows N does not have to be applied. However producers who decide to be risk adverse (in terms of yield) can apply N but it would be advised to do so at a reduce the rate. Now is a good time to note that the N-Rich Strip alone provides a Yes or No, not rate recommendation. At OSU we use the GreenSeeker optical sensor and Sensor Based Nitrogen Rate Calculator (SBNRC) to determine the rate, but that discussion will come later. I equate the change from using yield goal N rate recs to the N-Rich Strip as to going from foam markers to light bars on a sprayer. Not 100% accurate but a great improvement.

Now that we have covered the WHY, lets get down to the nuts and bolts HOW, WHEN, WHERE.

How the strip is applied has more to do with convenience and availability than anything else but there are a few criteria I suggest be met. The strip should be at least 10 ft wide and 300 ft long. The rate should be no less than 50 lbs N (above the rest of the field) for grain only wheat and canola, 80 lbs N for dual purpose wheat. The normal recommendation is that when applying pre-plant either have a second, higher rate programmed into the applicator or make a second pass over an area already fertilized. Many will choose to rent a pull type spreader with urea for a day, hitting each field.

Becoming more popular are applicators made or adapted for use. ATV sprayers are the most common as they can be multi-purpose. In most cases a 20-25 gallon tank with a 1 gpm pump is placed on the ATV with an 8-10ft breakover boom. The third applicator is a ride away sprayer with a boom running along the rear of the trailer. In all cases when liquid is the source I recommend some form of streamer nozzle. In most cases there is not a great deal of thought put into what source. I recommend whichever source is the easiest, cheapest, and most convenient to apply.

When the strip is applied in winter crops proper timing is regionally dependent. For the Central Great Plains, ideally the fertilizer should be applied pre-plant or soon after. However, in most cases as long as the fertilizer is down by the first of November everything works. This does not say a strip applied after this time doesn’t work but it leaves more room for error. There is a chance the crop could already be stressed or the nitrogen tied up and not release in time. However when the N-Rich Strip approach is used on the Eastern Shore in Virginia and Maryland the strips have to be applied at green up. The soils in that region are very deep sands and nitrogen applied in the fall may not make it to the spring. Also most wheat producers in the area make three or more applications of nitrogen unlike the two (pre and top) of the Great Plains. It is always important to make the tools fit your specific regional needs and practices and not the other way around.

Where is actually the biggest unknown. The basic answer is to place the N-Rich Strip in the area that best represents the field. Many people question this as it doesn’t account for spacial variability in the field, and they are correct. But my response is that in this case spatial variability is not the goal, temporal variability is. Keeping in mind the goal is to take a field which has been receiving a flat yield goal recommendation for the last 30+ years and make a better flat rate recommendation. My typically request is that on a field with significant variability either apply a strip long enough to cross the zones or apply smaller strips in each significant area. This allows for in-season decisions. I have seen some make the choice to ignore the variability in the field, made evident by the strip, and apply one rate and others choose the address the variability by applying two or more rates. One key to the placement of N-Rich Strips is record keeping. Either via notes or GPS, record the location of every strip. This allows for the strips to be easily located at non-response sites. It is also recommended to move the strip each year to avoid overloading the area with N.

I hear a great deal of talk about how it would take to much time to put out the N-Rich Strip. However the majority of producers that do it once on one field, end up doing it every year on every field. There is very likely someone in your area who is using the N-Rich Strips. As top-dress grows closer keep an eye out for a blog “Using the GreenSeeker Sensor and Sensor Based Nitrogen Rate Calculator”.

For more information on N-Rich Strips check out the YouTube video below, visit http://www.npk.okstate.edu or contact me directly at b.arnall@okstate.edu. I have lots of material I am happy to share and distribute.

See the YouTube Video http://www.youtube.com/watch?v=kJ3DSwWYgE8