Brian Arnall, Precision Nutrient Management Specialist

Samson Abiola, PNM Ph.D. Student.

Wheat Protein and Technology challenge

For wheat growers, achieving both high yields and good protein content is a constant challenge. Wheat contributes about 20% of the world’s calories, making it a vital crop for global nutrition. Every season, we face the question of how to boost grain protein concentration (GPC) without sacrificing the yield.

Traditional approaches often involve applying more nitrogen (N) early in the season. While this can help, it is often wasteful, environmentally problematic, and does not always translate to higher protein levels at harvest. The effectiveness of N applications depends not just on timing but also on the spray technology used, including the N source, nozzle type, and droplet size. While protein premiums are never guaranteed, we wanted to develop recommendations prior to the need.

The Research Approach: Timing and Technology

Our research team conducted a comprehensive three-year study (2019-2022) across three Oklahoma locations (Perkins, Lake Carl Blackwell, and Chickasha) to investigate how different combinations of N sources, nozzle types, and droplet sizes affect protein when applied during flowering. We considered two N sources (urea-ammonium nitrate (UAN) and aqueous urea [Aq. Urea]). We also evaluated three nozzle types: Standard flat fan (FF) nozzles with a traditional 110° spray angle, 3D nozzles with three-dimensional spray patterns that enhance canopy penetration, Twin (TW) nozzles with dual forward and rear facing sprays (30° forward and backward)

Finally, we tested both fine droplets (below 141 microns) and coarse droplets (≥141 microns). All applications were made at flowering i.e., when you start seeing yellow anthers sticking out of the wheat heads. Both UAN and Aq. urea were applied at a 20 gpa application rate with a 1:1 dilution with water delivering approximately 30 lbs. of N per acre.

What We Found: More Protein Without Hurting Yield

The big news? Spraying N at flowering boosted wheat protein by 12% without sacrificing yield. This held true across fields yielding anywhere from 30 to 86 bushels per acre. Why doesn’t it hurt yield? By flowering time, your wheat has already “decided” how many heads and kernels it will produce. The N you spray at this stage goes straight to building protein in those existing kernels.

One important caution: Mother Nature still calls the shots, so keep an eye on the forecast before planning your application. If the weather is hot and dry, this is not a good idea. First, those environments typically result in higher protein anyways. But low humidity will significantly increase the likelihood of burn.

Lake Carl Blackwell Findings: UAN Takes the Lead

At our Lake Carl Blackwell site, we saw our highest protein levels reaching up to 16.3% in some plots. In 2020-21, UAN clearly beat Aq. urea (14.7% vs. 14.0% protein). Both were much better than not applying any N at flowering (13.1%) (Figure 1A). Also, the 3D nozzle gave us the highest protein (14.7%), outperforming the control but performing similarly to FF (14.0%) and TW nozzles (14.2% (Figure 1B). The next year (2021-22) showed us something interesting, the combination of N source and droplet size really matters. UAN with fine droplets hit 14.6% protein, similar to UAN with coarse droplets (14.4%) and Aq. urea with coarse droplets (14.3%), but Aq. urea with fine droplets fell behind at just 13.8% (Figure 1C).

Chickasha Results: Matching Your N to the Right Droplet Size

At Chickasha, protein ranged from 10.1% to 13.8% across the two years we studied. In 2021-22, UAN beat Aq. urea (12.7% vs. 12.2%), and both beat the control (11.8%) (Figure 2A). Also, the 3D nozzle (12.8%) outperformed both FF and TW nozzles (both 12.2%) (Figure 2B).

In 2020-21, we found that the combination of N source, nozzle type, and droplet size all worked together to affect protein. The winning combination was UAN with 3D nozzle and fine droplets (13.23% protein), which performed similarly to Aq. urea with TW nozzle and coarse droplets (13.18%) (Figure 2C). The least performer was Aq. urea with TW nozzles and fine droplets (12.20%) among the treatments. This shows how weather and growing conditions can change which factors matter most from year to year

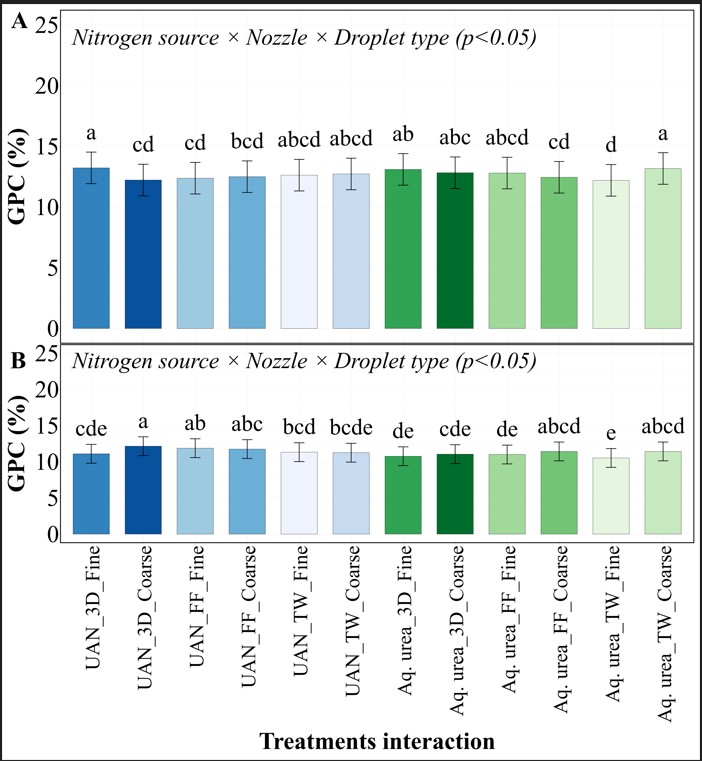

Perkins Results: Getting Every Detail Right

At our Perkins site, we saw protein levels ranging from 10% to 13.1%. Here, the combination of all three factors (N source, nozzle type, and droplet size) made a huge difference. The best setup was UAN with 3D nozzle and coarse droplets (12.2% protein). The worst was Aq. urea with TW nozzle and fine droplets (10.5%) (Figure 3). That’s a 15% difference that could mean the difference between premium and feed-grade wheat!

UAN consistently outperformed Aq. Urea across all setups. For example, UAN with 3D nozzle and coarse droplets produced 10% higher protein than the same setup with Aq. Urea.

Equipment and Application Recommendations

Over the three years UAN consistently outperformed perform Aq. urea, showing there is no need for a special formulation and that commercially available UAN is all we really need as a source. While no nozzle type significantly stood out across all sites the 3-D nozzle did show up a couple times as being statistically better. So the important message would be that while the high tech nozzles could provide some value the traditional flat fan performed quite well. While some differences were seen in droplet size, the lack of consistency leads us to say focus on good coverage with limited drift.

Take-Home Messages

- Foliar N at flowering boosted wheat protein by 12% without affecting yield multiple growing seasons and locations. This increase was from 0.5 to nearly 2.0 % protein.

- Nitrogen source matters – UAN consistently outperformed Aq. Urea.

- Your spray technology mattered but not lot – and 3D nozzles generally gave the best results. The good ole flat fans nozzles still did quite will.

- Match droplet size to your setup – generally fine for UAN and coarse for Aq. Urea.

- This targeted approach enhances grain quality without sacrificing yield, potentially improving grain prices and profitability while using N more efficiently.

- Mother Nature still calls the shots, so keep an eye on the forecast before planning your application. If the weather is hot and dry, this is not a good idea. First, those environments typically result in higher protein anyways. But low humidity will significantly increase the likelihood of burn.

This blog was written based upon the data published in the manuscript “Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement” which is available for free reading and downloading at https://www.mdpi.com/2077-0472/15/8/812

Any questions or comments feel free to contact me. b.arnall@okstate.edu

Assuming a pivot application at same timing would yield similar results?

Kerry,

Great question, and I would guess it would impact but at a lower magnitude. The N from this app is able to translocate through the plant tissue and reallocate into the grain. Fertigated will need to travel from root to grain, so I would think a flagleaf shot is better timing. Just a guess though.

My protocol is usually to pump last shoot at boot to heading, about 30#. we typically have pretty good protein but we do some sell some wheat for milling so that brings more attention to Protein. question are you running some 10-34-0 to reduce leaf burn with UAN from those late applications.

Not running any 10-34-0. Its been a a 1:1 UAN/H2O mix. As long as humidity is not to low it has been safe.